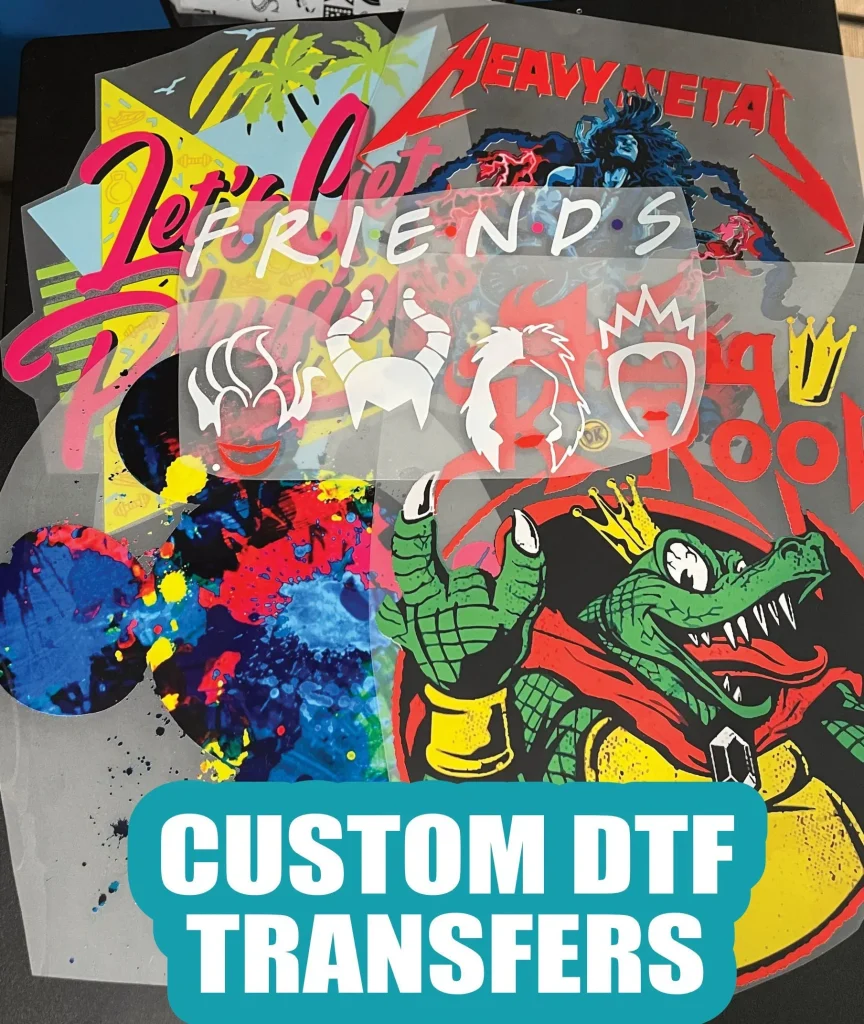

DTF transfers, or Direct-to-Film transfers, are at the forefront of a transformative wave within the custom printing industry. As traditional methods like screen printing are being re-evaluated, DTF technology offers a fresh perspective on apparel printing that is both innovative and efficient. With its ability to produce vibrant and intricate designs on various fabrics, DTF transfers stand out as a cost-effective printing solution that enhances creativity without sacrificing quality. This technology not only streamlines the printing process but also meets the growing demand for customization in a fast-paced market. As we explore the future of custom printing, it’s clear that DTF transfers are set to redefine industry standards and consumer expectations alike.

Direct-to-Film (DTF) printing represents a new era in personalized textile production, revolutionizing how designs are applied to apparel. This cutting-edge printing technique is gaining traction as a versatile alternative to traditional options like screen printing and direct-to-garment methods. DTF technology allows for breathtaking visual results with remarkable durability, making it a preferred choice for businesses aiming to provide high-quality custom designs. Moreover, the efficiency and flexibility of DTF transfers cater to a diverse range of materials, fostering creativity while optimizing cost-effectiveness. As the custom printing landscape evolves, the emergence of DTF solutions signifies crucial advancements that cater to both creators and consumers.

Understanding DTF Transfers in Custom Printing

Direct-to-Film (DTF) transfers represent a groundbreaking step forward in the custom printing industry. This innovative technique allows for the accurate reproduction of vibrant designs that are durable and long-lasting. As businesses in apparel printing look for solutions that enhance productivity and quality, DTF transfers emerge as a favored choice, supported by their ability to print on various fabric types, from cotton to polyester blends. This versatility empowers printing shops to diversify their offerings and cater to a wider audience.

Moreover, the technology behind DTF transfers ensures that prints retain their colors and details even after multiple washes. Unlike traditional methods like screen printing, which can fade over time, DTF prints shine for longer, which is pivotal for customer satisfaction and brand loyalty. As consumers increasingly prioritize quality in customized apparel, DTF technology becomes essential for businesses focused on delivering high standards.

The Advantages of DTF Technology Over Traditional Methods

DTF technology has gained traction due to its numerous advantages over conventional printing techniques such as screen printing. One key advantage is the simplified setup process for projects, which is particularly beneficial for printing shops that handle multiple orders at once. Instead of the lengthy and costly setup associated with traditional methods, DTF allows for printing multiple designs simultaneously on the same film, streamlining operations and reducing turnaround times.

Additionally, the cost-effectiveness of DTF transfers is significant for small to medium-sized businesses. The technology minimizes the financial burden by eliminating excessive setup costs and enabling the simultaneous printing of different designs, which is especially appealing in a competitive marketplace that values speed and efficiency. This operational efficiency ultimately translates to substantial savings that can be passed on to customers, enhancing competitive positioning in the industry.

DTF Transfers: A Versatile Solution for Various Fabrics

One of the standout benefits of DTF transfers is their compatibility with a diverse range of fabrics. This flexibility is particularly important for businesses involved in custom printing, as it allows them to cater to a wider assortment of apparel items. Whether it involves T-shirts, hoodies, or accessories like bags and caps, DTF technology adapts seamlessly to various materials without compromising print quality or durability.

This versatility not only expands the potential product range for printing shops but also facilitates faster execution of customer requests. In an industry where trends can change rapidly, the ability to print on multiple fabric types allows businesses to stay agile and responsive to market needs, which is invaluable for maintaining a competitive edge.

Cost-Effective Printing Solutions with DTF Transfers

In today’s fast-paced market, cost efficiency is paramount, and DTF transfers shine as a budget-friendly printing solution. Traditional printing methods such as screen printing often entail high overhead costs, particularly related to setup and labor. DTF technology, on the other hand, mitigates these concerns by allowing for quick changes between designs and colors without the extensive setup typically required.

This cost-saving aspect of DTF is especially beneficial for smaller printing operations that may struggle with high operational expenses. By adopting DTF technology, these businesses can lower their production costs, which can lead to lower prices for their customers, creating a win-win scenario that supports both profitability and customer satisfaction.

Durability of DTF Printed Apparel

Durability is a critical concern in the custom printing industry, as customers seek products that maintain their appearance over time. DTF transfers excel in this category, producing prints that withstand frequent washing and wear. Unlike some traditional methods that may result in fading or peeling, DTF-printed garments offer impressive longevity without sacrificing color vibrancy or detail.

The advanced formulations used in DTF ink technology contribute to the resilience of these prints, making them more appealing to consumers who value quality. As businesses emphasize quality assurance in their offerings, the durability of DTF-printed apparel becomes a significant selling point, enhancing customer trust and encouraging repeat purchases.

The Growing Market Potential of DTF Printing

As the demand for personalization in products continues to rise, the market potential for DTF transfers is immense. Research indicates that the shift towards online shopping, combined with consumer preferences for unique and individualized items, places DTF technology in a prime position to capture this growing market. Businesses leveraging DTF can effectively respond to these trends by offering high-quality, custom products with quick fulfillment times.

This expanding market is not only limited to apparel; as DTF technology evolves, its applications are likely to broaden, thus providing businesses with opportunities to innovate. Entrepreneurs in the printing space should take proactive steps to incorporate DTF technology into their operations, ensuring they remain adaptable and in line with consumer expectations as the market continues to evolve.

The Future Offering of DTF Transfers in Custom Printing

As the custom printing industry progresses, DTF transfers are set to play a pivotal role in shaping its future. With an increasing number of businesses recognizing the benefits of DTF technology, we can expect a rise in adoption rates across various sectors. The innovative nature of DTF printing aligns perfectly with the modern consumer’s demand for unique and personalized goods, making it a vital component of future printing strategies.

Looking ahead, the combination of enhanced DTF technologies and evolving consumer preferences will likely spark further innovations within the realm of custom printing. Businesses that embrace this technology not only stand to improve efficiency and product quality but also position themselves as leaders in a transforming industry, ready to meet the demands of the next generation of consumers.

Frequently Asked Questions

What are DTF Transfers and how do they work in custom printing?

Direct-to-Film (DTF) transfers are a revolutionary custom printing technology that involves printing vibrant designs onto a specialized film. This film is then used to transfer the graphics onto various apparel materials, offering superior quality compared to traditional methods like screen printing.

Why are DTF Transfers considered a cost-effective printing solution?

DTF transfers are considered cost-effective because they require minimal setup for color changes and allow multiple designs to be printed simultaneously on the same film. This reduces both overhead and labor costs, making it an ideal choice for small to medium-sized printing businesses looking to maximize profits.

How do DTF Transfers compare to screen printing in terms of flexibility?

DTF transfers offer greater flexibility than screen printing. They can be used on a wide variety of fabrics, including cotton, polyester, and blends, making them suitable for diverse apparel items from t-shirts to caps, unlike screen printing which requires separate setups for each color.

What advantages do DTF Transfers provide in terms of durability?

DTF transfers are known for their exceptional durability, as prints maintain their vibrancy and integrity even after multiple washes. This durability ensures customer satisfaction and long-term value in the custom apparel market, outperforming many traditional printing methods.

Can DTF Transfers be used for intricate designs?

Yes, DTF transfers excel at printing intricate and detailed designs. The DTF technology allows for vivid colors and sharp details, making it perfect for complex graphics that might be challenging to achieve with traditional printing methods like screen printing.

What is the market potential for DTF Transfers in the custom printing industry?

The market potential for DTF transfers is significant, with growing recognition of its advantages. As consumer demand for personalized products increases and online shopping becomes more prevalent, DTF technology is positioned to fulfill these needs, driving growth in the custom printing sector.

| Key Point | Details |

|---|---|

| Introduction to DTF Transfers | A new method that revolutionizes custom printing across various materials. |

| Revolutionizing Apparel Printing | DTF Transfers offer high-quality prints with vibrant colors that endure through washes. |

| Flexibility and Convenience | Compatible with various fabrics and allows faster turnarounds, enhancing customer satisfaction. |

| Cost-Effectiveness | Reduces overhead costs and labor with simplified processes and minimized setups required for printing. |

| Durability and Quality | DTF transfers provide exceptional wash resistance and color retention, enhancing consumer satisfaction. |

| Market Potential | The DTF printing market is growing rapidly as businesses seek efficient, personalized printing solutions. |

Summary

DTF Transfers herald a new era in custom printing, significantly transforming the industry with their innovative approach. This technology provides high-quality, versatile, and cost-effective solutions, making them an essential competitor to traditional printing methods. With their proven durability and ability to cater to diverse materials, DTF transfers are well-positioned to meet the increasing market demand for personalized products. As more businesses adopt this technology, the future of apparel printing and customization looks bright, ensuring that DTF Transfers will continue to revolutionize the industry.