DTF transfers, or Direct-to-Film transfers, are redefining the landscape of t-shirt printing with their innovative approach to customization and quality. This cutting-edge technology allows for vibrant, durable prints that appeal to both casual consumers and professional designers alike, making it a game-changer for custom apparel. As sustainability becomes a central theme in the fashion industry, DTF printing technology stands out by minimizing waste and reducing the use of harmful materials, aligning with the growing demand for eco-friendly practices. The unique benefits of DTF transfers, such as versatility across various fabrics and superior print durability, elevate their status in the competitive market of t-shirt printing. In this exploration, we will delve into how DTF transfers not only enhance artistic expression but also promote a more sustainable future for the apparel industry.

In the world of custom printing, Direct-to-Film technology has emerged as a revolutionary solution that elevates traditional methods of creating personalized garments. This innovative transfer technique, favored by many for its unique capabilities, enables artists and businesses to produce high-quality images on various materials with ease. The enduring appeal of DTF printing lies in its adaptability and the vibrant results it achieves, providing an exceptional experience for creators. As the demand for eco-conscious practices rises, manufacturers are adopting this method to meet consumer expectations while promoting sustainable printing initiatives. By examining alternative terms and perspectives surrounding DTF printing, we can appreciate its significant impact on the future of custom apparel.

Understanding DTF Printing Technology

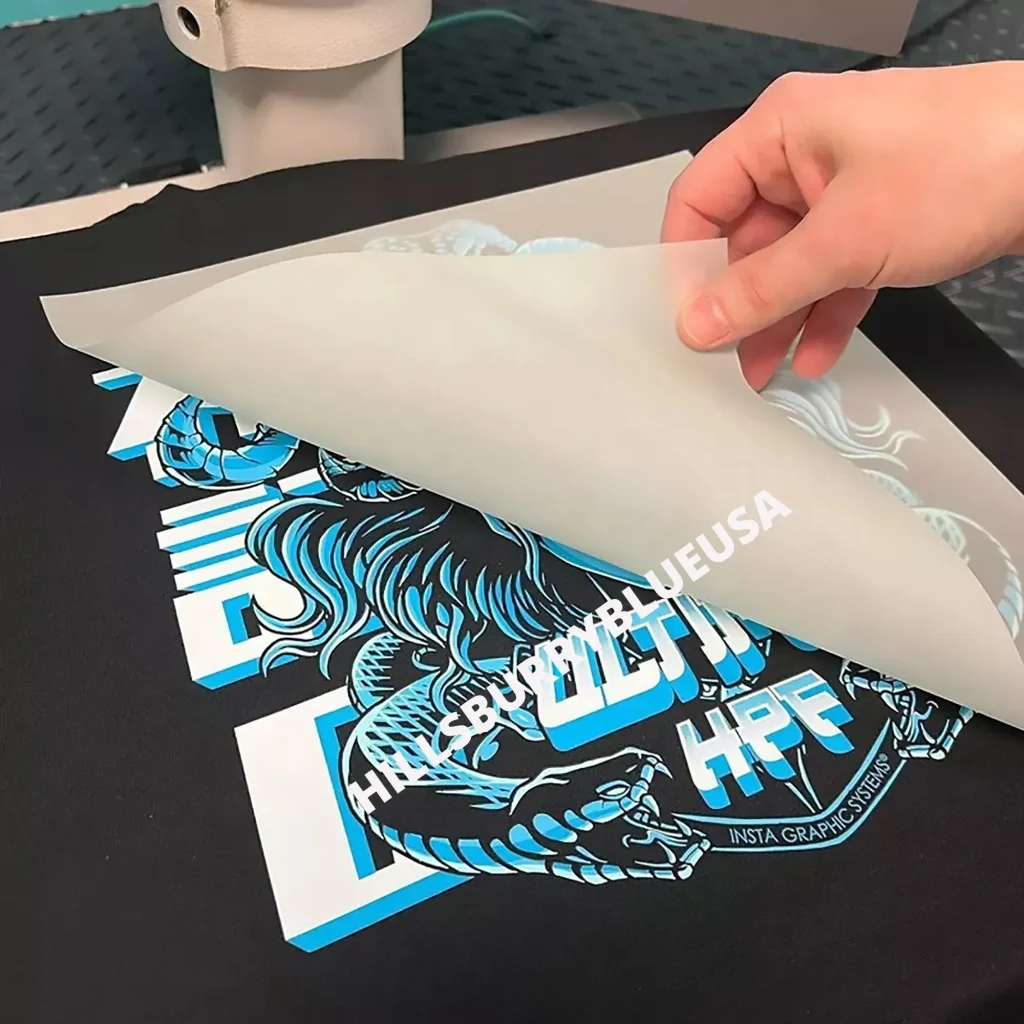

DTF printing technology, or Direct-to-Film printing, represents one of the latest innovations in the realm of t-shirt printing. This method involves printing designs onto a special film, which is then transferred onto fabric using heat and pressure. What sets DTF apart is its ability to produce vibrant colors and intricate designs with remarkable precision. Unlike traditional screen printing, where color limitations often pose challenges, DTF allows for full-color images with easy gradients and complex artwork, making it an excellent choice for custom apparel.

Another significant aspect of DTF technology is its adaptability. It can be utilized on a variety of materials including cotton, polyester, and blends, which broadens the scope of projects crafters can undertake. This flexibility ensures that small businesses and hobbyists alike can experiment with different fabrics, fulfilling diverse consumer demands. Moreover, DTF prints adhere well to various surfaces, unlike other methods that might limit the choices of fabric, thus encouraging innovation in custom design.

The Sustainable Edge of DTF Transfers

Sustainability has become a pivotal concern within the apparel industry, and DTF transfers provide a promising solution. Traditional printing methods often generate excessive waste and require harmful chemicals, so eco-friendly alternatives are gaining traction. DTF printing not only reduces material waste but also minimizes the carbon footprint associated with production. This pioneering method utilizes water-based inks, which are less toxic and safer for both the environment and the individuals handling them, aligning with the growing demand for sustainable practices in t-shirt printing.

The integration of sustainable printing methods like DTF reinforces the notion that businesses can be both profitable and eco-conscious. Innovators in the industry are now prioritizing sustainability as a core value, with companies leveraging DTF technology to produce fewer emissions during the printing process. For consumers looking to support environmentally-friendly products, choosing apparel printed with DTF transfers represents a step towards responsible consumption.

Benefits of DTF Transfers for Crafters

For crafters and creators, DTF transfers open up an exciting world of opportunities. The ease of transferring detailed designs onto fabrics without the lengthy setup times associated with traditional methods enhances the crafting experience. Hobbyists can simply print their designs onto a film and, within minutes, transfer high-quality images onto their apparel. This convenience is especially appealing for small businesses and entrepreneurs who need to quickly produce custom items for customers.

The versatility offered by DTF technology also allows crafters to explore more creative avenues. With the capability to print on different materials and the ability to blend colors seamlessly, artists can bring their visions to life more effectively. Custom designs are not only limited to t-shirts but extend to a wide range of apparel, including hoodies and tote bags, which can dramatically broaden a crafter’s potential customer base.

Comparative Performance of DTF vs. Other Printing Methods

When weighing the comparative advantages of DTF printing against other common techniques such as screen printing or sublimation, the former emerges as a versatile leader. For instance, while sublimation is typically restricted to synthetic materials like polyester, DTF can be applied to a broader range of fabrics, including natural fibers. This versatility allows manufacturers to target more diverse markets without needing multiple machines for various products.

Moreover, DTF printing provides durability that surpasses many traditional printing methods. DTF prints are capable of withstanding multiple washes and everyday wear without losing vibrancy or experiencing wear and tear. This durability ensures that custom items maintain their quality over time, offering peace of mind for consumers who invest in personalized apparel. As businesses and creators evaluate their printing options, the long-lasting benefits of DTF transfers continue to make them an attractive choice.

Navigating the Challenges of DTF Printing

Despite the numerous benefits of DTF printing, potential challenges cannot be overlooked. Initial setup costs can be a concern for new entrepreneurs looking to invest in equipment, as the technology requires specialized printers and materials. While these expenses may seem daunting, they should be evaluated against the potential return on investment garnered from the high-quality products that can be offered to customers.

Another challenge is ensuring quality control throughout the DTF printing process. Achieving optimal results necessitates a thorough understanding of the required materials and machinery settings. While users may face a learning curve initially, investing time in mastering the DTF process pays off by enhancing the quality of the end product. As the printing landscape evolves, continuous education and adaptation will be key to overcoming these challenges.

The Future of Custom Apparel with DTF Transfers

With the rise of DTF transfers, the landscape of custom apparel is poised for significant transformation. As consumers increasingly seek personalized products, businesses that adopt DTF printing can effectively meet these demands. This technology not only accommodates detailed and custom designs but does so with efficiency, allowing businesses to fulfill orders quickly and maintain high customer satisfaction levels.

Furthermore, the potential for innovation in design processes is boundless. As DTF technology continues to evolve, we can expect enhancements in print quality and environmental impact, reflecting the broader trends toward sustainability in the fashion industry. In this rapidly changing market, DTF printing is set to become a cornerstone of custom apparel, driving creativity and inspiring more creators to explore their artistic visions.

Frequently Asked Questions

What are the benefits of using DTF transfers for t-shirt printing?

DTF transfers offer several benefits for t-shirt printing, including high durability, vibrant color reproduction, and compatibility with a wide range of fabrics like cotton and polyester. This method minimizes waste and uses eco-friendly inks, making it a sustainable choice for custom apparel. Additionally, DTF transfers allow for quick production times, enabling small businesses and creators to meet consumer demands effectively.

How does DTF printing technology compare to traditional t-shirt printing methods?

DTF printing technology surpasses traditional methods by offering better versatility in fabric options and enhanced durability of prints. While methods like sublimation are limited to polyester fabrics, DTF works on various materials, including cotton and leather. DTF transfers also produce prints that resist fading and wear over time, making them ideal for apparel intended for long-term use.

Is DTF transfer printing a sustainable option for custom apparel production?

Yes, DTF transfer printing is a sustainable option for custom apparel production. It reduces waste compared to traditional t-shirt printing methods and utilizes eco-friendly inks that minimize environmental impact. As the fashion industry seeks sustainable practices, DTF printing aligns well by providing high-quality prints with a reduced carbon footprint.

Can individual crafters benefit from DTF transfers for their t-shirt designs?

Absolutely! Individual crafters can greatly benefit from DTF transfers for their t-shirt designs. This printing method offers a wide array of possibilities, allowing for intricate graphics and full-color designs. DTF technology empowers crafters to create unique, high-quality custom apparel without the limitations of traditional printing methods.

What challenges might I face when using DTF transfers for t-shirt printing?

While DTF transfers offer numerous advantages, some challenges include the initial setup costs, which may be higher compared to traditional printing methods, and the need for quality control. Users must invest time in learning the DTF printing process and understanding materials to achieve the best results. However, as technology becomes more accessible, these barriers are likely to lessen.

Why is DTF printing becoming popular in the t-shirt printing industry?

DTF printing is gaining popularity in the t-shirt printing industry due to its unique blend of sustainability, versatility, and efficiency. It meets the rising demand for environmentally friendly practices while allowing creators and businesses to produce high-quality custom apparel quickly. DTF technology’s durability and adaptability make it a preferred choice for both individual creators and larger companies alike.

| Key Point | Details |

|---|---|

| Sustainability | DTF printing minimizes waste, uses eco-friendly inks, and reduces carbon footprints, making it a sustainable choice. |

| Consumer Options | DTF technology allows crafters to create custom designs with vibrant and long-lasting prints. |

| Material Versatility | DTF excels on various fabrics like cotton, polyester, canvas, and leather, unlike sublimation which is limited to polyester. |

| Durability | DTF prints are known for their resilience against washing and wear, maintaining vibrant colors. |

| Efficiency | DTF printing streamlines operations, allowing for quicker turnaround and responses to consumer demand. |

| Challenges | Initial setup costs can be higher and quality control is crucial for achieving desired results. |

Summary

DTF transfers are revolutionizing t-shirt printing by introducing a highly efficient, sustainable, and versatile method for producing high-quality prints. This innovative technology addresses the modern demands for eco-friendly practices in the fashion industry while offering an exceptional array of customization options for both individual creators and small businesses. With greater durability compared to traditional printing methods, DTF prints stand out in longevity and vibrancy, making them an appealing choice in today’s market. As the industry continues to shift toward these advancements, the adoption of DTF transfers not only transforms how apparel is made but also signifies a cultural movement towards responsible consumerism and creative expression.