DTF transfers are revolutionizing the world of custom apparel printing by combining the efficiency of Direct to Film printing with the high-quality output expected by today’s consumers. This innovative technology allows for vibrant, full-color designs to be easily transferred onto a wide range of fabrics, making it a superior choice compared to traditional screen printing methods. The advancements in printing technology underpinning DTF transfers not only enhance production speed but also cater to the growing demand for personalized apparel. As businesses strive to stay competitive in a saturated market, embracing the advantages of DTF printing is essential for those looking to thrive in the custom apparel landscape. In this article, we’ll explore how DTF transfers represent the future of textile printing, driven by technological innovation and market trends.

In the realm of digital apparel decoration, Direct to Film transfers stand out as a groundbreaking method that offers unique printing solutions for fashionable clothing items. Characterized by its ability to produce intricate designs with remarkable clarity and durability, this technique offers a compelling alternative to traditional screen printing. The rise of this printing method reflects a significant shift towards more versatile and customizable options for brands and businesses seeking to make their mark in the fashion industry. With its seamless integration into various production workflows, DTF printing is reshaping how custom apparel is created and personalized. As industries continue to evolve, the embrace of such cutting-edge printing methodologies signifies an important trend in the future of fabric decoration.

Understanding DTF Transfers and Their Impact on Printing

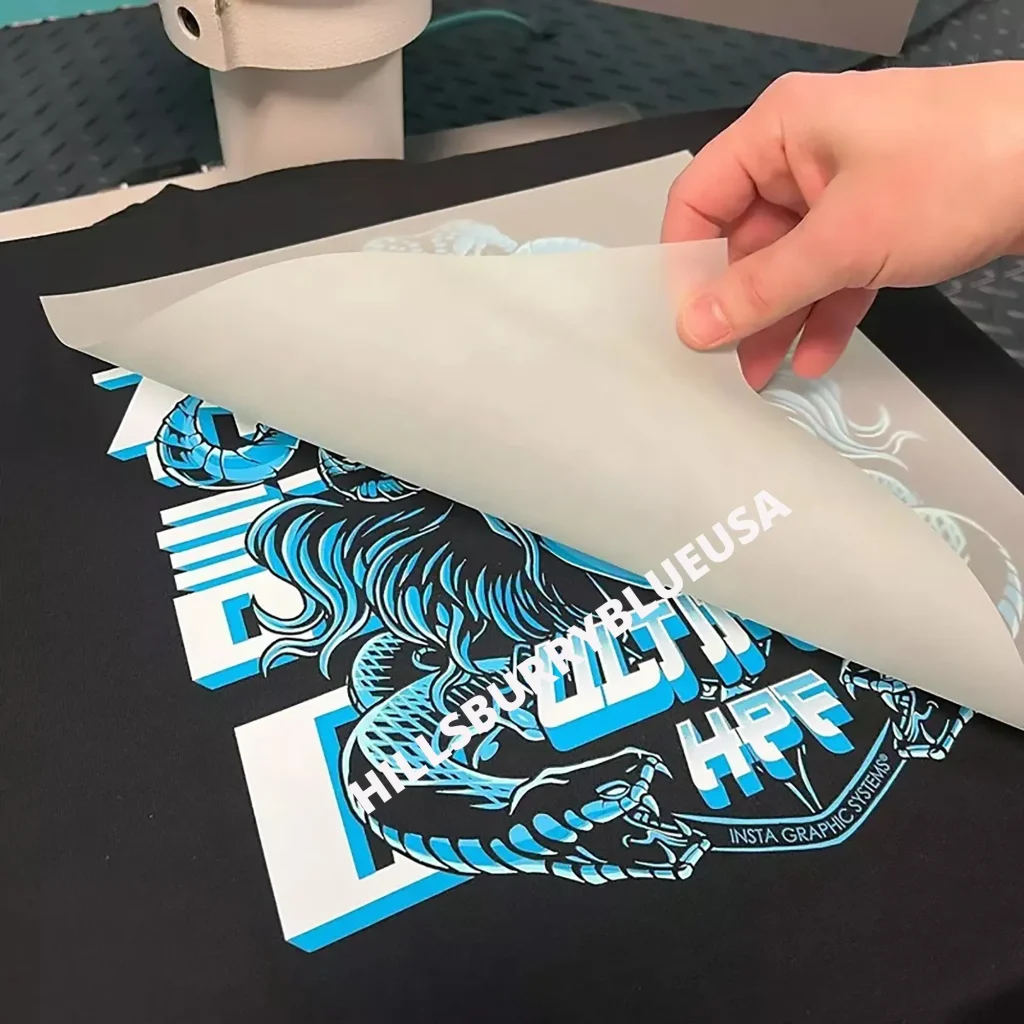

DTF transfers, short for Direct to Film transfers, represent a significant evolution in the printing landscape, marrying the benefits of traditional screen printing with the technology of digital prints. By utilizing a specialized film, DTF printing creates vibrant designs that are seamlessly transferred onto fabrics. This process not only appeals to businesses looking for custom apparel solutions but also offers a quicker turnaround time compared to conventional methods. With the rapid advancements in printing technology, DTF transfers are setting a new standard for quality and efficiency.

The impact of DTF transfers extends beyond mere convenience. This method enables the production of intricate designs with sharp details and a wide range of colors, catering to a growing consumer demand for personalization and uniqueness in apparel. As e-commerce rises, companies utilizing DTF printing can respond faster to market trends, providing personalized products that resonate with buyers. This integration of quality and speed positions DTF transfers as a pivotal component in the future of custom apparel printing.

Frequently Asked Questions

What are DTF transfers and how do they work in custom apparel printing?

DTF transfers, or Direct to Film transfers, are a printing method where designs are printed onto a specialized film, which is subsequently transferred onto fabrics using heat and pressure. This process blends the advantages of traditional screen printing with the flexibility of digital printing, making it ideal for creating custom apparel.

What are the key advantages of DTF printing over traditional screen printing?

DTF printing offers several advantages over traditional screen printing, including faster production times, the ability to print intricate designs in vibrant colors, and no minimum order quantities. These benefits make DTF transfers a preferred choice for businesses seeking efficient and high-quality custom apparel solutions.

How has technological advancement impacted the popularity of DTF transfers?

Recent advancements in printing technology, including the introduction of efficient DTF printers and heat transfer presses, have significantly boosted the popularity of DTF transfers. These innovations streamline workflows, reduce operation costs, and enable businesses of all sizes to adopt DTF printing without high initial investments.

Why is DTF printing considered a game-changer for small businesses in the custom apparel market?

DTF printing is a game-changer for small businesses because it allows for quick turnaround times without the constraints of traditional screen printing processes. It enables small companies to offer personalized and unique designs on demand, catering to the growing consumer demand for custom apparel.

What types of materials can DTF transfers be applied to?

DTF transfers can be applied to a wide range of materials, including cotton, polyester, and blends. This versatility makes DTF printing a popular choice for producing custom apparel, as it accommodates various fabric types while maintaining high-quality prints.

How is the global demand for DTF printing evolving?

The global demand for DTF printing is rapidly increasing, as businesses recognize its capabilities and benefits. Developments like the launch of new DTF printers in various regions highlight the adaptability and appeal of DTF technology in the international market for custom apparel.

| Key Points | Description |

|---|---|

| Introduction to DTF Transfers | Printing method using specialized film for transferring designs onto fabrics, combining screen printing and digital printing benefits. |

| The Rise of DTF Printing | Emerging as a favored solution in custom apparel, catering to diverse clients with fast, no-minimum services—especially in e-commerce. |

| Technological Advancements | Innovative equipment, such as ROQ IMPRESS, enhances efficiency; affordable printing technology enables small businesses to enter the market. |

| International Market Growth | Global demand is surging, with developments like AM.CO.ZA’s A3 DTF printer supporting print-on-demand markets. |

| Efficiency and Versatility | DTF printing allows full-color prints with less complexity, suitable for various applications, making it accessible for both professionals and amateurs. |

Summary

DTF transfers are becoming a cornerstone in the evolution of screen printing, merging cutting-edge technology with an ever-growing versatility that meets modern demands. As businesses increasingly seek quick, personalized printing solutions, DTF transfers prove to be pivotal in staying competitive. Their ability to deliver high-quality, intricate designs efficiently makes them not only a practical choice but also a game-changing innovation for the custom apparel industry. Embracing DTF technology is essential for businesses that aim to thrive in today’s fast-paced market, cementing their status as leaders in the printing revolution.