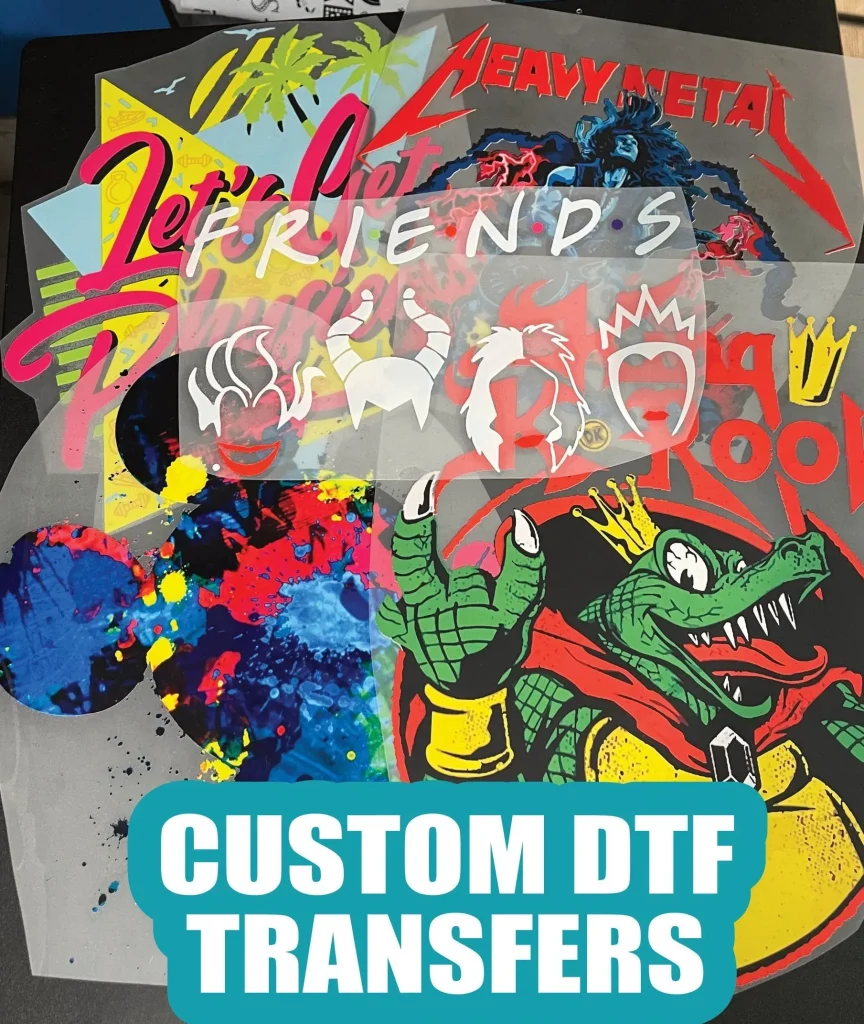

DTF transfers, or Direct to Film transfers, are revolutionizing the garment printing industry with their innovative approach. This cutting-edge method utilizes the DTF printing process, allowing for high-quality designs that are both vibrant and durable on various fabric types. The benefits of DTF transfers extend beyond just aesthetic appeal; they offer exceptional efficiency and versatility, making them ideal for both small batch and large-scale productions. As market trends in DTF printing indicate a growing preference for personalized and custom apparel, understanding this technology is becoming increasingly important for garment producers. In this comprehensive guide, we’ll delve deeper into the world of DTF transfers, exploring their advantages, processes, and emerging trends within the industry.

Direct to Film printing, often referred to as DTF technology, is rapidly emerging as a favored choice among apparel decorators and designers. This exciting printing method involves transferring intricate designs onto a specially coated film, which can then be easily applied to a range of fabrics. The versatility and efficiency associated with this approach make it a popular alternative to traditional screen printing and Direct to Garment methods. As the demand for unique and customized clothing continues to rise, the adoption of DTF printing processes aligns perfectly with market needs. This guide will explore the nuances of this innovative technique and its implications for the future of fabric decoration.

What You Need to Know About DTF Printing Technology

DTF printing technology has revolutionized the fabric printing sector by offering high-quality output at a low cost. By utilizing advanced eco-solvent inks, this method allows for printing intricate and vibrant designs onto a film, which is then transferred to garments. The sustainable nature of these inks aligns with growing consumer preferences for environmentally friendly products, making DTF printing not only innovative but also responsible. Furthermore, as the market increasingly leans towards digital solutions, DTF printing stands out by integrating technology to meet both artistic and practical needs.

Another remarkable feature of DTF technology is its adaptability across various fabric types. Unlike traditional printing methods, which may require extensive preparation and pre-treatment for different materials, DTF transfers can seamlessly work on everything from cotton to polyester. This versatility makes it an ideal choice for businesses looking to cater to a wide range of customer demands, ensuring that they can fulfill orders promptly while maintaining high standards of quality.

Advantages of Using DTF Transfers for Fabric Printing

The benefits of DTF transfers extend beyond mere functionality; they also promise superior results that can significantly enhance a business’s offerings. One of the most significant advantages is the incredible durability and vibrancy of the prints produced. Unlike other methods, DTF prints exhibit astonishing color retention and resilience, making them ideal for both everyday wear and specialty items. This durability translates to customer satisfaction, as garments retain their aesthetic appeal even after multiple washes.

Moreover, DTF transfers streamline the printing process, allowing for faster turnaround times. This quick setup is particularly beneficial for small businesses or startups that may not have the resources to commit to large-scale production runs. As a result, DTF printing becomes a smart investment, especially for brands focusing on custom designs or limited-edition collections that can attract various audiences.

Understanding the DTF Printing Process in Detail

The DTF printing process is a carefully executed series of steps that guarantees high-quality results. Initially, designs are printed onto specially formulated PET film using high-resolution, eco-friendly inks. This stage is crucial as it sets the foundation for the quality of the final product. Following this, a hot-melt adhesive is applied to ensure that the print will adhere effectively to the fabric during heat transfer.

The culmination of the process involves a heat press that firmly attaches the design to the garment. This stage is not merely about applying heat but involves precision in temperature and timing to ensure that the transfer retains its integrity and resists fading or peeling. Mastery of this process is essential for anyone looking to maximize the advantages of DTF transfers.

Market Trends Influencing the Growth of DTF Printing

The market trends in DTF printing showcase a significant shift towards personalized and custom apparel, with an increasing number of businesses adopting this technology. This growing consumer demand for unique and tailored products reflects a broader movement in the fashion industry, where individuality is becoming a key selling point. As brands pivot to offer more personalized options, DTF printing emerges as a prime avenue through which companies can meet their customers’ desires.

Furthermore, as technological advancements continue to improve print quality and efficiency in DTF printing, more businesses are likely to incorporate these techniques into their operations. Innovations such as faster printers and enhanced adhesive formulations are making it easier for companies to produce high-quality prints at scale, driving further interest and investment in DTF technology.

Exploring the Benefits of DTF Printing for Small Businesses

For small businesses, the introduction of DTF transfers can be transformative. The ability to produce high-quality prints in small batches means that even startups can offer custom designs without the financial burden typically associated with large-scale production. This flexibility allows entrepreneurs to experiment with various designs and styles while keeping costs manageable, ensuring that they can respond quickly to market trends.

Additionally, DTF printing’s compatibility with a wide range of fabrics enables small businesses to diversify their product offerings. Whether creating T-shirts, hoodies, or even home textiles, the versatility of DTF technology opens up numerous avenues for creativity and revenue generation, positioning these businesses for sustainable growth in a competitive market.

Challenges and Considerations in DTF Printing Implementation

Despite its numerous advantages, implementing DTF printing is not without its challenges. The initial cost of acquiring the necessary equipment, including advanced DTF printers and heat presses, can be daunting for smaller businesses. However, understanding the long-term savings and potential revenue growth that come with high-quality DTF outputs can help to mitigate these upfront costs.

Moreover, the learning curve associated with DTF technology can pose additional hurdles. Understanding material specifications, ink settings, and adhesive applications requires training and practice. However, many businesses find that investing in staff training pays off in the form of improved product quality and customer satisfaction.

Frequently Asked Questions

What is DTF printing and how does it work?

DTF printing, or Direct to Film printing, is a process where designs are printed onto a special film using eco-solvent or water-based inks. This film is then applied to fabric using heat and pressure, allowing for vibrant, high-quality prints that adhere well to various materials.

What are the benefits of DTF transfers compared to traditional printing methods?

The benefits of DTF transfers include versatility on a wide range of fabrics without pre-treatment, cost-effectiveness for low minimum orders, and exceptional durability of prints. This makes DTF printing ideal for custom designs and small batch productions.

What materials can DTF transfers be applied to?

DTF transfers can be applied to almost any fabric, including cotton, polyester, and blends. This flexibility allows for applications on both light and dark fabrics, making DTF printing a highly versatile option for various garment types.

What are the key steps in the DTF printing process?

The DTF printing process involves three main steps: first, printing the design onto a PET film; second, applying a hot-melt adhesive to the printed film; and finally, using a heat press to transfer the design onto the fabric firmly.

What are the current market trends in DTF printing for 2023?

In 2023, the DTF printing market is experiencing rapid growth, driven by advancements in ink and film technology. There is an increasing demand for personalized fashion and custom apparel, as consumers continue to seek unique designs, making DTF a promising area for businesses.

What challenges should businesses consider when adopting DTF printing technology?

Businesses considering DTF printing should be aware of the initial investment costs for printers and heat press equipment, as well as the learning curve associated with mastering the printing process. Adequate training is essential to optimize settings for different fabrics.

| Key Point | Details |

|---|---|

| What is DTF Printing? | DTF is a printing technique where designs are printed on a PET film and then transferred to fabric using heat. This allows for vibrant and durable prints. |

| Key Features | Exceptional quality, compatibility with various fabrics, and simplified setup compared to traditional methods. |

| DTF Printing Process | Involves three steps: printing on PET film, applying hot-melt adhesive, and heat transferring to fabric. |

| Benefits of DTF Transfers | Versatile on light and dark fabrics, cost-effective for small orders, and highly durable. |

| Market Trends | Rapid market expansion driven by advancements in technology and rising consumer demand for customization. |

| Challenges | Initial setup costs and a learning curve associated with mastering the printing process and equipment. |

Summary

DTF transfers are revolutionizing the fabric printing industry, combining quality, versatility, and efficiency. As companies seek innovative solutions to meet consumer demands, mastering DTF transfers becomes essential for creative and production success. With its ability to cater to varied fabric types and deliver vibrant, durable designs, DTF transfers are poised to expand their presence significantly in customized apparel and promotional items. As the technology continues to evolve, understanding DTF transfers will be key to harnessing their full potential and staying competitive in the fast-paced market.