DTF transfers are revolutionizing the custom printing industry by offering a unique and effective way to create vibrant designs on fabric. With the rise of DTF printing technology, many businesses are discovering the benefits of this method, particularly when it comes to producing high-quality, durable prints for apparel and promotional items. Choosing the best DTF transfers can be a critical factor in ensuring that the final product meets both aesthetic and durability standards. In this guide, we will delve into essential criteria for selecting top-notch DTF transfers, focusing on aspects such as transfer quality and material compatibility. Whether you’re a seasoned print professional or just starting, understanding how to choose DTF transfers will enhance your printing projects significantly.

Direct-to-Film transfer methods are becoming increasingly popular among printing enthusiasts seeking vibrant and long-lasting designs. Often praised for their efficiency and quality, these innovative printing solutions offer an exciting alternative to traditional screen printing. As you explore the world of DTF transfer options, it’s essential to understand the factors that contribute to high-quality images and effective application techniques. By evaluating transfer attributes like adhesion, washing durability, and color fidelity, you can ensure that your printed products will stand out in a competitive market. This introductory overview aims to provide insights into maximizing the potential of DTF transfer technology for a variety of textile printing projects.

What Are DTF Transfers and Why Are They Popular?

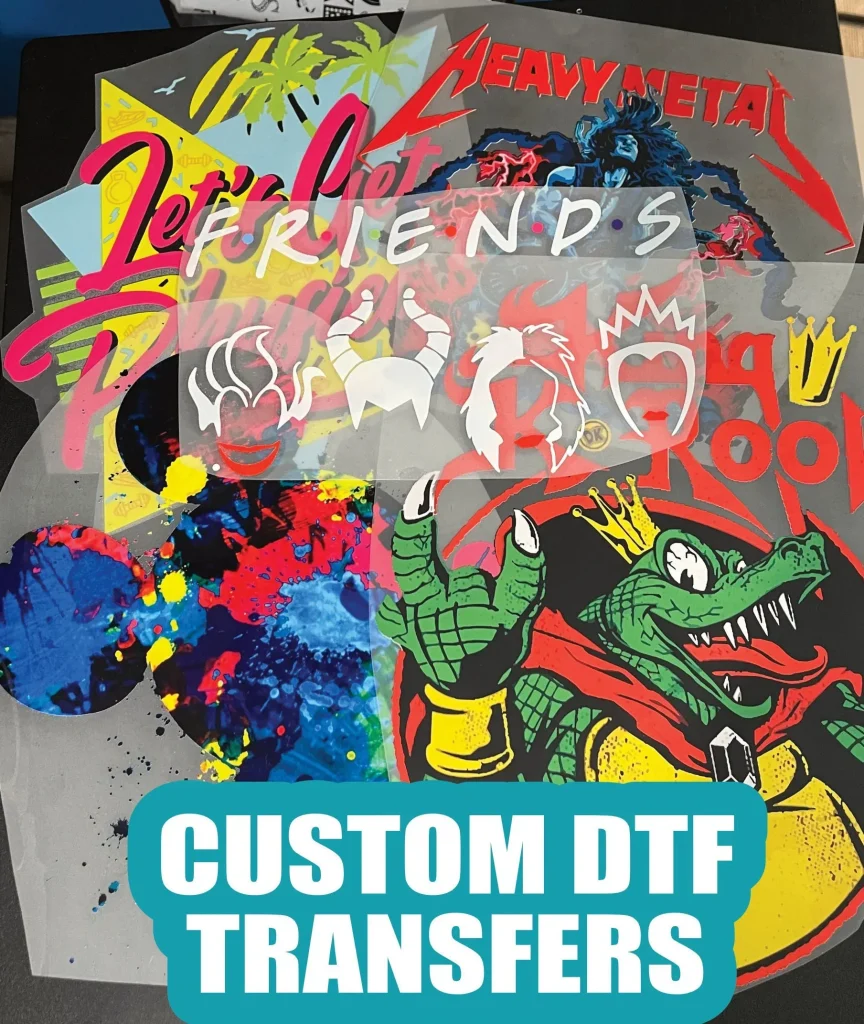

Direct-to-Film (DTF) transfers have emerged as a leading option in the world of custom printing. They involve a unique process where images are printed onto a special film using high-quality inks. This method, which utilizes heat to adhere the image to fabric, allows for vibrant, long-lasting prints that can withstand numerous washes without fading. The popularity of DTF transfers is largely due to their versatility across various textiles, making them ideal for custom apparel, promotional merchandise, and more.

The appeal of DTF transfers also lies in their ability to produce high detail and color accuracy. Unlike traditional screen printing methods, DTF can efficiently reproduce intricate designs with vibrant colors, thus meeting the demands of modern consumers who seek personalized and unique items. As more printers and suppliers begin to adopt DTF technology, its market presence continues to grow, driven by increasing consumer demand for customization and quality.

Evaluating Material Quality for DTF Transfers

When selecting DTF transfers, material quality is paramount. The transfer film must be compatible with both light and dark fabric applications while providing excellent wash durability. High-quality films ensure that prints retain their vibrancy and integrity even after repeated laundering. This means evaluating the ink formulations as well—water-based inks are preferred due to their environmentally friendly properties, as well as their capability to produce vivid colors that remain true over time.

Moreover, the durability of the transfers is critical for customer satisfaction. Choosing transfers that are designed to withstand multiple washes without significant degradation ensures that clients are happy and likely to return for additional services. Always consider seeking out samples or product reviews to ascertain the transfer quality before making a bulk purchase, as this can save both time and resources in the long run.

Ensuring Printing Technology Compatibility

Choosing the right DTF transfers also involves understanding your printing technology. DTF printing requires specific inkjet printer setups and modified systems to optimize the printing process. Not all DTF transfers will work seamlessly with every printer, so ensuring compatibility is key to achieving high-quality outputs. For those already invested in certain printing technologies, it’s crucial to work with suppliers who offer products compatible with existing machines.

Many leading manufacturers are now developing DTF systems that easily integrate into printing workflows, enhancing not only efficiency but also productivity. By selecting suppliers that understand the intricacies of DTF printing technology, businesses can streamline their operations while also improving print quality. Therefore, researching and verifying that the chosen DTF transfers align with your technology can make a significant difference in workflow efficiency.

Color Fidelity and Design Fidelity in DTF Printing

Color fidelity is essential in the realm of DTF printing, as it directly impacts the appeal of the finished product. To achieve stunning prints, transfers should provide a broad color gamut, allowing for the accurate reproduction of vibrant designs. It’s recommended to opt for transfers that are celebrated for their ability to replicate intricate details, which is particularly vital when printing logos or complex graphics.

In addition to examining color fidelity, it’s beneficial to investigate customer reviews related to color accuracy and print performance. Feedback from other users can provide invaluable insights into how well a specific brand’s transfers perform in various scenarios. By prioritizing transfer products known for excellent color and design fidelity, print providers can enhance customer satisfaction and build a strong reputation in the marketplace.

Testing Adhesion and Wash Durability of DTF Transfers

Before committing to specific DTF transfers, conducting tests to assess adhesion and wash durability is a crucial step. Reliable DTF transfers should adhere effectively to different fabric types and show minimal signs of wear even after extensive washing—ideally maintaining quality up to at least 30 washes. This kind of rigorous testing helps ensure that your final product not only meets client expectations but can also withstand everyday use.

Additionally, many reputable suppliers offer sample packs of their DTF transfers, allowing you to evaluate performance in real-world applications without risk. By taking advantage of these samples, print service providers can make informed purchasing decisions that align with their quality standards and customer needs. Such proactive measures significantly enhance the likelihood of delivering consistently high-quality products.

Understanding Environmental Considerations in DTF Printing

With the growing trend towards eco-friendly practices, it’s important to consider the environmental impact of the DTF transfers you select. Increasingly, consumers are becoming aware of sustainability and are more inclined to choose products that minimize harm to the planet. As such, sourcing DTF transfers made from sustainable materials not only appeals to this environmentally-conscious demographic but can also position your business as one that values ecological responsibility.

While some eco-friendly DTF transfers may come at a slightly higher price point, the long-term benefits often outweigh the costs. Not only do these products attract environmentally aware customers, but they can also enhance your brand’s reputation. As you explore your options, look for suppliers who prioritize sustainable production processes, as these selections can provide great marketing opportunities while fulfilling client expectations for eco-friendly solutions.

Frequently Asked Questions

What are the best DTF transfers for vibrant color printing?

The best DTF transfers for vibrant color printing are those that utilize high-quality water-based inks and films designed for optimal durability. Look for brands that are known for their color fidelity and wash durability, ensuring that your printed designs maintain their vividness even after multiple washes.

How do I choose the right DTF transfers for my printing needs?

When selecting the right DTF transfers, consider factors such as the material quality, printing technology compatibility, color fidelity, adhesion, and wash durability. Additionally, researching customer reviews and supplier reputation can guide you in finding the best options for your specific printing projects.

What should I look for regarding DTF transfer quality?

DTF transfer quality can be observed through the vibrancy of the inks, the durability of the film after washing, and the ability to reproduce intricate designs. High-quality DTF transfers should maintain their appearance over time and provide consistent results across different types of fabrics.

What is DTF printing technology and its advantages?

DTF printing technology involves printing designs onto a special film which is then heat-pressed onto fabric. Its advantages include the ability to produce vibrant colors, high durability, and compatibility with various textiles, making it a preferred choice for custom apparel and promotional items.

How can I ensure the adhesion and longevity of DTF transfers?

To ensure the adhesion and longevity of DTF transfers, it is crucial to test them on different fabrics and check their performance after washing. Look for high-quality products that claim to withstand at least 30 washes while maintaining color and design integrity.

Why is supplier reputation important when choosing DTF transfers?

Supplier reputation is important because it reflects product quality, customer service, and reliability in delivery. Sourcing DTF transfers from reputable suppliers can provide reassurance of consistent quality and support, which is essential for successful printing operations.

| Key Points | Details |

|---|---|

| Material Quality | Evaluate transfer film and inks. Look for vibrant ink quality and durability. |

| Printing Technology Compatibility | Ensure transfers work with your printer’s setup. Look for integrated systems. |

| Color and Design Fidelity | Transfers should support a broad color range, retaining fine details. |

| Adhesion and Wash Durability | Test product adherence to fabrics; should last through multiple washes. |

| Cost-Effectiveness | Analyze total cost, including supplies, for good ROI. |

| Supplier Reputation | Source from reliable suppliers with good customer support and delivery. |

| Environmental Considerations | Select eco-friendly products to meet consumer demand. |

Summary

DTF transfers are an essential aspect of custom printing projects that require careful consideration in selection. Key factors to keep in mind include the quality of materials, compatibility with printing technology, color reproduction fidelity, adhesion, wash durability, cost-effectiveness, supplier reputation, and environmental considerations. By focusing on these critical elements, print service providers can significantly enhance both the quality of their printed products and customer satisfaction. As the DTF transfer market continues to grow and evolve, staying informed about industry advancements will empower you to make well-informed decisions that lead to successful printing outcomes.