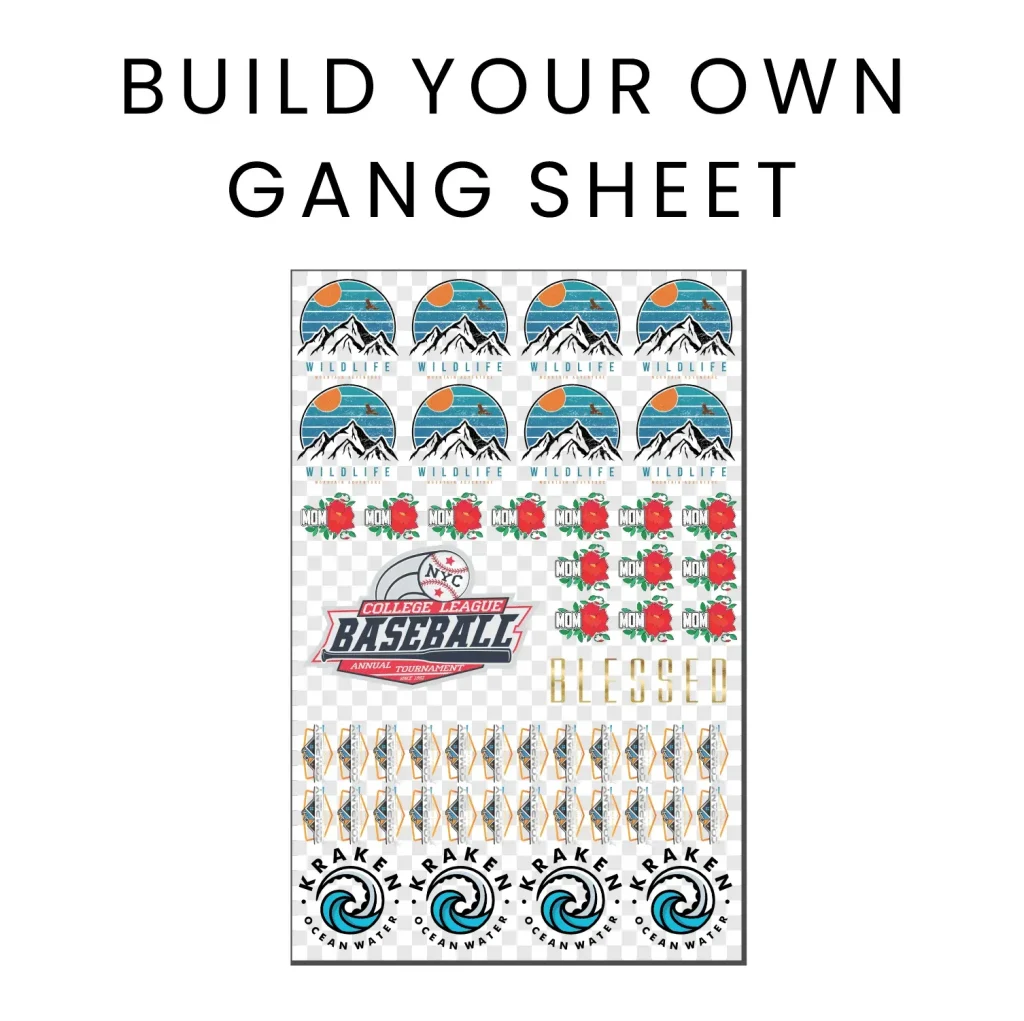

Maximize your printing efficiency with a DTF gangsheet builder, an essential tool for modern print manufacturers and small businesses alike. In the competitive landscape of printing, streamlining operations is paramount to reducing costs and boosting profitability. Direct-to-Film (DTF) printing has revolutionized the way we think about custom transfer printing, and gang sheets are at the forefront of this transformation. By allowing multiple designs to be printed simultaneously, DTF gangsheet builders not only save time but also minimize material waste, ensuring a more economical production process. This introductory guide delves into how harnessing the power of DTF gangsheet builders can elevate your printing game and enhance your creative capabilities.

In the realm of custom printing, Direct-to-Film (DTF) printing stands out as a cutting-edge solution that optimizes efficiency and quality. A DTF gangsheet creator, often associated with gang sheets, enables users to print multiple images on a single film, addressing the needs of both small-scale creators and large printing operations. The emergence of streamlined tools facilitates better management of printing resources, leading to substantial savings and minimal waste. This innovative approach to custom transfer printing not only enhances productivity but also expands design possibilities for businesses eager to fulfill diverse client requests. With the evolving landscape of DTF printing, understanding gang sheets becomes critical for any creator looking to maximize their output.

The Significance of DTF Printing in Modern Print Manufacturing

Direct-to-Film (DTF) printing has revolutionized the print manufacturing landscape. Its ability to deliver high-quality images while being time-efficient has made it a favorite among businesses of all sizes. With the integration of DTF printing, manufacturers can now offer customized solutions that cater to their clientele’s distinct needs without compromising on quality. This adaptability has not only enhanced customer satisfaction but has also paved the way for businesses to scale their operations effectively.

By embracing DTF printing, companies are uncovering new revenue streams, as they can now cater to niche markets and personalized consumer demands. This versatility in production allows printers to experiment with various substrate materials, ensuring they remain competitive while maximizing production efficiency. As a result, businesses leveraging DTF technology find themselves at the forefront of innovation in the printing ecosystem.

Maximizing Efficiency with DTF Gangsheet Builders

One of the primary advantages of using a DTF gangsheet builder is the substantial increase in printing efficiency it offers. This tool allows printers to arrange multiple designs onto a single sheet, dramatically reducing the time spent on setup and minimizing waste of film materials. By consolidating production, users not only save costs but also enhance productivity, which is crucial in today’s fast-paced market.

Moreover, the streamlined process that comes with gangsheet builders provides businesses with the agility to respond to client orders more effectively. By enabling quick adjustments and the ability to print a variety of designs simultaneously, companies can meet diverse client needs with ease. This operational efficiency translates into increased profitability and positioning within the competitive printing market.

Understanding the Cost-effectiveness of Gang Sheets

Cost-efficiency in printing is an essential metric that influences the bottom line of any printing business. The utilization of gang sheets in DTF printing significantly reduces material wastage, ensuring every part of the film is used effectively. This reduction in material waste is not only cost-effective but also environmentally friendly, contributing to sustainable business practices.

In addition to savings on materials, gang sheets also minimize labor costs associated with setting up individual prints. When multiple designs can be printed in a batch, less time is spent on preparations and adjustments. Thus, businesses can operate with fewer resources while maximizing output, further enhancing their financial sustainability.

Innovations Driving DTF Printing Forward

As technology continues to evolve, so too does the DTF printing landscape. Recent innovations, such as customized transfer printing services, have emerged to address the unique challenges faced by creative professionals. These advancements not only simplify the design creation process but also allow for personalization, which is increasingly in demand among consumers looking for bespoke products.

Furthermore, the introduction of compact A3 DTF printers is making it easier for smaller businesses to enter the market. By providing equipment that enhances user accessibility and efficiency, manufacturers are opening the doors to a new wave of creativity in print-on-demand services. This drive towards innovation presents significant opportunities for growth and expansion in the DTF printing sector.

Tips for Efficient Custom Transfer Printing

Ensuring efficiency in custom transfer printing goes beyond choosing the right equipment; it also involves optimizing the design and layout of prints. Utilizing advanced design software tools to create efficient gang sheets can lead to significant material savings and a smoother operational flow. By focusing on these aspects, printers can streamline their processes and improve overall output quality.

Additionally, regularly experimenting with different materials and printing techniques allows businesses to continuously refine their practices. Staying informed about the latest trends and innovations in the DTF printing world will also equip printers with the knowledge necessary to enhance operational strategies. Embracing this proactive approach can lead to higher printing efficiency and greater customer satisfaction.

Preparing for the Future of DTF Printing

Preparing for the future in the DTF printing industry means anticipating changes and remaining agile. With customer demands constantly evolving, printers must be willing to adapt their strategies and embrace new technologies. Investments in high-quality DTF gangsheet builders and state-of-the-art equipment will position businesses to better meet these changing needs.

In addition, building strong relationships with suppliers can enhance the adaptability and diversity of available materials. By ensuring a steady supply of quality products, printers can maintain a competitive edge, allowing them to cater to all aspects of the market efficiently. Future-proofing operations in this way will sustain long-term growth and profitability in the DTF printing arena.

Frequently Asked Questions

What is a DTF gangsheet builder and how does it improve printing efficiency?

A DTF gangsheet builder is a specialized tool that enables the simultaneous printing of multiple designs onto a single film in Direct-to-Film (DTF) printing. This significantly enhances printing efficiency by reducing setup times, minimizing material waste, and lowering production costs, allowing for a more cost-effective and streamlined printing process.

How do gang sheets work in Direct-to-Film printing?

Gang sheets in Direct-to-Film printing allow various designs to be printed on one sheet, optimizing the printing process. This technique reduces printing time and material costs while also enabling printers to cater to diverse client requests, enhancing overall operational efficiency and output.

What are the benefits of using a DTF printing gangsheet builder for custom transfer printing?

Using a DTF printing gangsheet builder for custom transfer printing offers several benefits, including increased efficiency by printing multiple designs at once, reduced material waste with less excess film, and the versatility to easily combine different designs tailored to customer specifications, thus driving greater client satisfaction.

Can a DTF gangsheet builder help scale my printing operations?

Yes, a DTF gangsheet builder can significantly scale your printing operations. By allowing the simultaneous printing of multiple designs, it helps meet high-volume order demands efficiently, making it ideal for both small-scale creators and large printing businesses looking to increase their production capacity.

What should I look for when choosing a DTF gangsheet builder for my printing business?

When choosing a DTF gangsheet builder, consider factors such as its compatibility with different printer models, ease of use, design optimization features, and the ability to minimize material waste. Investing in quality equipment is essential to maximize your printing efficiency and ultimately enhance your business profitability.

How does utilizing gang sheets contribute to environmental sustainability in DTF printing?

Utilizing gang sheets in DTF printing contributes to environmental sustainability by significantly reducing material waste. Since gang sheets allow for multiple designs to be printed on a single film, they lower the amount of excess film used, making this approach not only cost-effective but also more eco-friendly, aligning with sustainable printing practices.

| Key Points | Description |

|---|---|

| Maximizing Efficiency | Efficiency reduces costs and increases profitability. |

| Understanding Gang Sheets | Allows multiple designs to be printed on a single film, minimizing waste. |

| Key Benefits | Increased efficiency, reduced material waste, versatility, scalability. |

| Recent Innovations | Introduction of custom transfer printing services and compact A3 printers. |

| Tips for Efficiency | Invest in quality equipment, optimize designs, experiment with materials, stay updated. |

Summary

DTF gangsheet builder is essential for maximizing your printing efficiency. As the print manufacturing landscape evolves, embracing tools like DTF gangsheet builders allows businesses, whether small or large, to optimize their production processes. By facilitating the simultaneous printing of multiple designs, these builders reduce material waste and streamline workflows. Investing in quality equipment and staying informed about industry advancements ensures that your printing operations remain competitive and cost-effective. With the integration of innovative solutions, businesses can not only meet diverse client demands but also boost their profitability significantly.