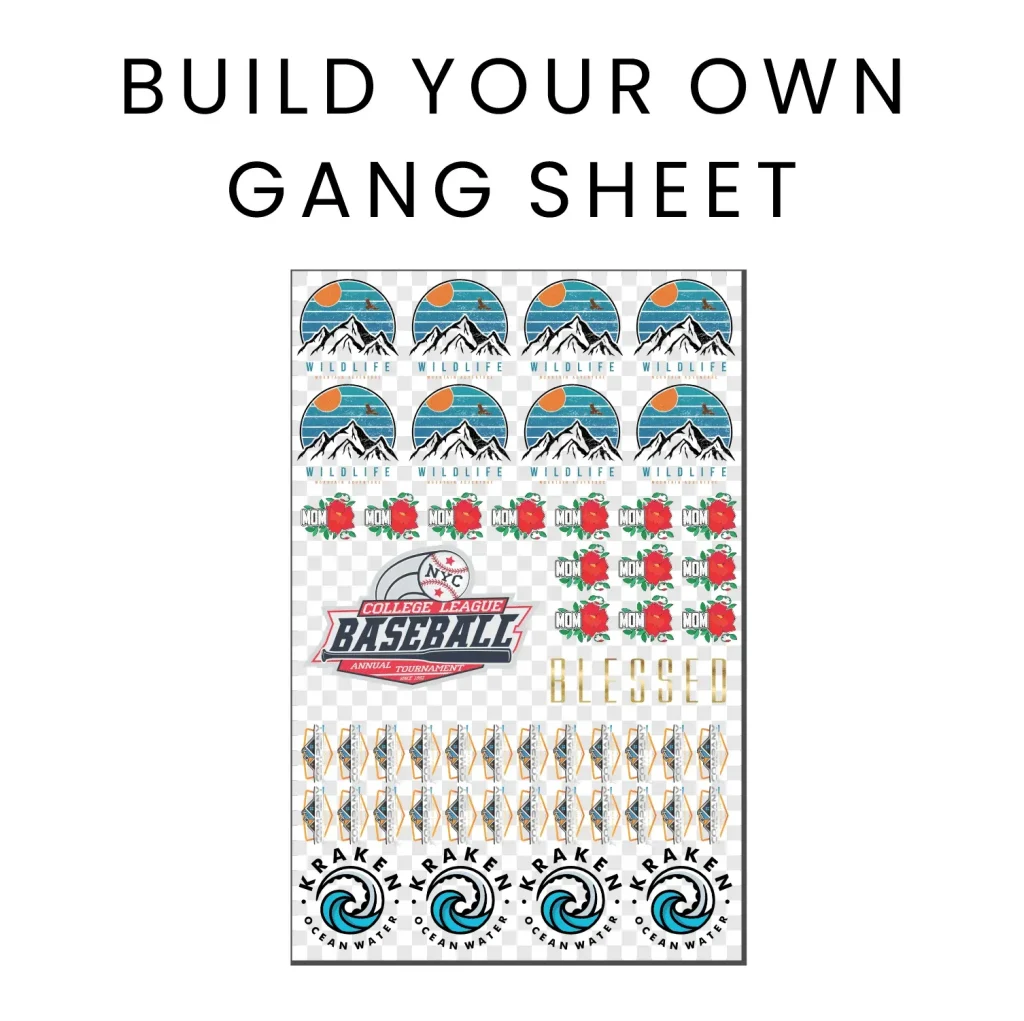

In the fast-paced world of custom apparel, the DTF gangsheet builder emerges as a game-changer for enhancing printing efficiency. This innovative tool streamlines the DTF (Direct-to-Film) printing process by allowing multiple designs to be printed simultaneously on a single film sheet. By maximizing the use of available space and minimizing waste, it not only cuts down on material costs but also accelerates production times, making it ideal for businesses looking to increase profitability. With the growing demand for high-quality, vibrant prints, leveraging a DTF gangsheet builder can significantly optimize print operations while delivering exceptional results. As we explore the benefits of this advanced technology, you’ll discover how it aligns perfectly with the evolving needs of today’s apparel industry.

In the realm of fabric printing, tools such as the Direct-to-Film gangsheet optimizer are revolutionizing the way designs are transferred to textiles. This approach, often referred to as gang sheet printing, allows businesses to arrange multiple artworks on a single sheet for efficient production. The rising trend of custom clothing requires print optimization strategies that ensure quality while reducing costs, and features of this unique builder help achieve those goals. By adopting this innovative method, printers can enhance their workflow while catering to the increasing consumer demand for personalized apparel. With advancements in technology, the standard for printing efficiency is being redefined, positioning businesses for success in a competitive marketplace.

Maximizing Printing Efficiency with DTF Technology

DTF printing stands as a revolution in the printing industry, primarily due to its capacity to deliver vibrant, high-quality designs with remarkable efficiency. With its straightforward application process, this method allows businesses to manage complex orders while maintaining the quality of prints. Understanding DTF printing’s mechanics can significantly impact the production pace and quality, thereby enhancing overall operational efficiency.

When compared to traditional printing techniques, DTF printing excels in versatility. It can cater to a wide range of fabrics, ensuring that businesses can expand their offerings without investing in multiple systems. This adaptability is crucial for companies aiming to meet diverse customer demands, making DTF printing an essential tool for maximizing efficiency in modern apparel production.

The Importance of Gangsheet Printing in DTF

Gangsheet printing optimizes material usage in the printing process, which is particularly crucial in a world where cost savings and sustainability matter more than ever. By placing several designs on a single DTF gangster sheet, printers can minimize waste and maximize their resources. This strategy allows for a more efficient printing process, which is beneficial for both large orders and smaller custom jobs.

Furthermore, gangsheet printing plays a significant role in expediting production times. It enables printers to handle multiple orders at once, ensuring designs are printed in clusters rather than one at a time. This not only speeds up the overall workflow but also helps businesses to meet tight deadlines, thus improving customer satisfaction and potentially leading to repeat orders.

Utilizing a DTF Gangsheet Builder

A DTF gangsheet builder enhances the efficiency of the printing process by allowing users to create optimized layouts quickly. This innovative tool lets printing companies arrange multiple designs onto a single sheet, thus improving space utilization. By adapting the placement of each design, businesses can achieve maximum output with minimal input—reducing waste and lowering costs.

Moreover, the integration of advanced software features in gangsheet builders allows for greater customization. Print operators can easily adjust designs to fit different dimensions, ensuring that every inch of material is utilized effectively. The ability to export these optimized layouts directly into printing files further streamlines the process, making it a seamless addition to any printing operation.

Technological Advances in DTF Printing

The advancements in DTF printing technology are making it easier for printers to enhance their production capabilities. Modern DTF printers are equipped with sophisticated gangsheet builders that allow for precise design alignment and optimization. These tools not only improve accuracy and reduce errors during the print process but also facilitate greater creativity, enabling businesses to take on more complex and high-demand projects.

Additionally, the latest software solutions offer real-time data analytics which helps printers evaluate their efficiency levels. By analyzing print runs and outcomes, companies can identify areas for improvement and implement changes that lead to better quality and faster prints. This modernization in DTF technology signals a future where businesses can compete effectively while ensuring customer satisfaction.

Cost Savings through Print Optimization

Implementing DTF gangsheet printing leads to significant cost savings for apparel businesses. By utilizing fewer materials through efficient layout arrangements, printers can reduce ink consumption and film waste, directly impacting their operating costs. The dual advantage of lesser material costs and optimized printing time enhances the financial performance of any printing operation.

Beyond immediate cost savings, businesses also benefit from the enhanced capability to fulfill larger and more diverse orders without incurring extra charges. This allows for an increase in revenue opportunities as companies can expand their customer base by offering unique products without the concern of elevated production costs.

The Future of Custom Apparel with DTF Printing

As consumer demand for custom apparel continues to grow, DTF printing technology stands at the forefront of this trend. Companies that adapt to using DTF gangsheet builders are poised for success in a market that increasingly favors on-demand printing capabilities. The versatility and efficiency of this technology allow for rapid responses to changing consumer preferences, ensuring business sustainability.

Moreover, as advancements in DTF printing and gangsheet techniques progress, we can expect even greater customization options to emerge. This evolution not only caters to consumer desires for personalization but also enhances the quality of products available in the market, setting a new standard in the custom apparel space.

Frequently Asked Questions

What is a DTF gangsheet builder and how does it enhance printing efficiency?

A DTF gangsheet builder is a software tool designed to optimize the layout of multiple designs on a single sheet of film for DTF printing. By grouping various images onto one gangsheet, printers maximize material usage, reduce waste, and cut down on production time, significantly enhancing overall printing efficiency.

How does DTF printing differ from traditional printing methods?

DTF printing utilizes a film and adhesive transfer process to apply designs onto fabric, making it simpler and more versatile than traditional methods. Unlike direct application techniques, DTF allows for designs to be printed on film and stored until needed, contributing to streamlined workflows and vibrant outputs.

What are the cost-saving benefits of using a DTF gangsheet builder?

Using a DTF gangsheet builder reduces printing costs significantly by requiring fewer sheets for multiple designs, lowering material expenses. Additionally, the efficient use of film minimizes waste, leading to overall cost savings in printing production.

How does gangsheet printing improve turnaround times for custom apparel orders?

Gangsheet printing, enabled by a DTF gangsheet builder, allows multiple designs to be printed at once, drastically improving turnaround times for custom apparel orders. This efficiency ensures that businesses can fulfill customer demands faster without compromising on quality.

What technological advancements are driving the effectiveness of DTF gangsheet builders?

Recent technological advancements have led to user-friendly features in DTF gangsheet builders, such as grid alignment for precise design placement, adjustable size options for individual images, and streamlined exporting of print-ready files, making it easier for printers to optimize layouts.

Why is the adoption of DTF printing and gangsheet builders growing in the printing industry?

The adoption of DTF printing and gangsheet builders is growing due to the increasing demand for custom apparel and on-demand printing. Businesses that implement these technologies see improvements in productivity, reduced costs, and elevated customer satisfaction, making them more competitive in the market.

| Key Points | Description |

|---|---|

| DTF Printing | A method that utilizes special film and adhesive for transferring designs onto fabrics. |

| Gang Sheet | A printing sheet that contains multiple designs to enhance production efficiency by reducing waste and maximizing material usage. |

| Efficiency Improvements | 1. Optimized layouts, 2. Reduced printing costs, 3. Time savings, 4. Decrease in ink and film waste. |

| Technological Developments | Modern DTF gangsheet builders offer intuitive features for layout optimization, including grid alignment, size adjustments, and export options. |

| Industry Adoption | Increased use of gangsheet builders across various sectors has improved productivity and enhanced customer satisfaction. |

| Market Outlook | As demand for custom apparel grows, the adoption of DTF printing and gangsheet techniques will expand, focusing on efficiency and speed. |

Summary

The DTF gangsheet builder is an essential component for enhancing efficiency in any printing operation. By adopting this innovative tool, businesses can streamline their workflows, reduce costs, and produce higher-quality products while meeting the increasing demand for customized apparel. As the industry evolves and technology advances, utilizing a DTF gangsheet builder will be crucial for staying competitive and achieving operational excellence.