In the rapidly evolving realm of textile printing, **DTF gangsheet builder techniques** have become a game-changer for those looking to enhance their Direct-to-Film (DTF) printing processes. This innovative approach allows designers to efficiently batch their artwork onto a single transfer film, maximizing both production efficiency and cost-effectiveness. By mastering these techniques, businesses can unlock numerous **DTF printing benefits** such as reduced material usage and improved print quality. Additionally, gangsheet design optimization plays a crucial role in ensuring that every inch of fabric is utilized beautifully, leading to vibrant, eye-catching prints. As the industry shifts towards more sustainable DTF techniques, these methods become increasingly vital for remaining competitive and eco-conscious.

Exploring the world of **gangsheet production strategies** unveils a treasure trove of possibilities for enhancing the Direct-to-Film printing experience. Often referred to as the backbone of efficient textile design, these methods emphasize the art of combining multiple motifs onto a single sheet for printing. This not only streamlines the workload but also highlights the adaptability and versatility of the DTF approach to various materials. Additionally, the integration of **economical printing solutions** ensures that print service providers maintain profitability while delivering exceptional quality. By harnessing these advanced techniques, businesses can meet the growing demands of today’s market while emphasizing sustainability and innovation in their craft.

Understanding the Advantages of DTF Printing

Direct-to-Film (DTF) printing has gained immense popularity due to its ability to produce high-quality prints with vibrant colors and intricate details. Unlike traditional screen printing methods, which often require lengthy setup processes, DTF printing simplifies the production workflow. This technique allows designers to apply ink directly onto a transfer film that can be easily adhered to various fabrics, such as cotton and polyester, making it a versatile choice for apparel and promotional products. The ease of use and flexibility of DTF printing have made it a go-to solution for many businesses looking to elevate their printing capabilities.

In addition to its simplicity, DTF printing offers significant cost benefits, which is critical for businesses operating on tight budgets. With advances in DTF technology, companies can now print full-color designs in smaller quantities without sacrificing quality or incurring high costs. This cost-effectiveness is especially advantageous for small to medium-sized businesses that may not have the capacity for large-volume orders. Furthermore, the durability and washability of DTF prints ensure long-lasting results, optimizing the investment for businesses and their customers.

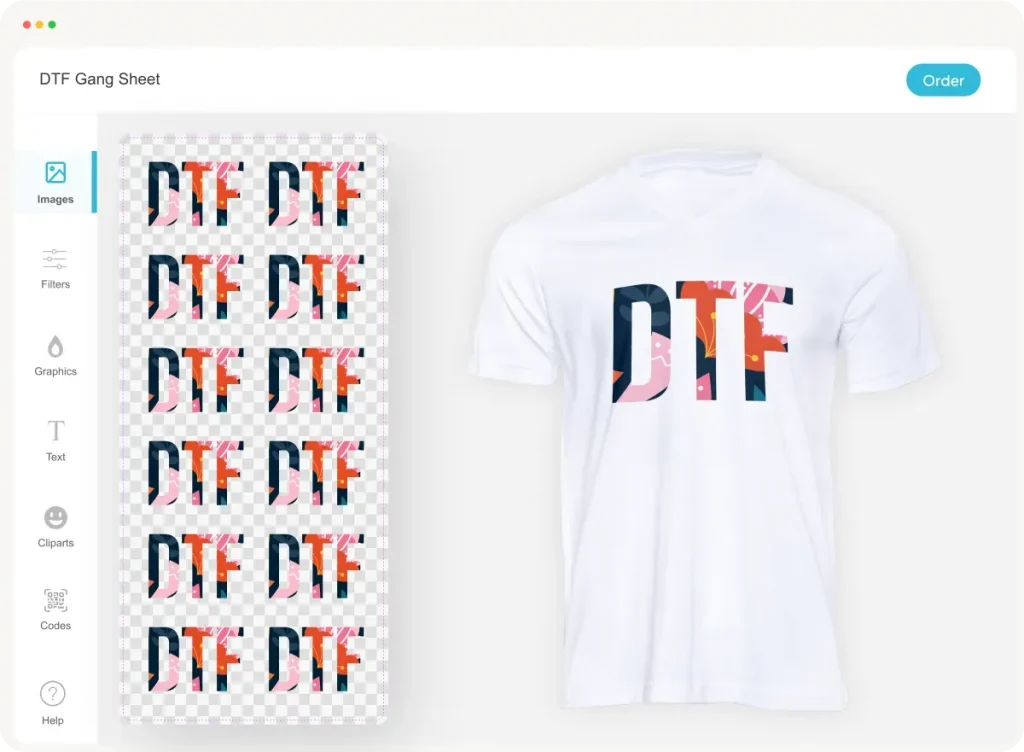

Exploring DTF Gangsheet Builder Techniques

DTF gangsheet builder techniques are revolutionizing the way prints are managed within the DTF printing process. A gangsheet allows multiple designs to be printed simultaneously on a single sheet of transfer film, maximizing the use of materials and reducing waste. This innovative approach not only streamlines production but also minimizes the overall costs associated with direct-to-film printing. Using a gangsheet can also improve the efficiency of workflow, as designers only need to prepare one film for printing multiple designs, making it an efficient option for high-volume orders.

Incorporating DTF gangsheet builder techniques requires precise planning and layout optimization. Designers need to effectively arrange their artwork to ensure that spacing prevents any overlap during the transfer process. Through the use of graphic design software, such as Adobe Illustrator, designers can make strategic decisions on layout to enhance the overall aesthetic of the print while optimizing cost and material usage. With proper use of gangsheet builder techniques, businesses can achieve optimal design placement, resulting in cleaner and more professional-looking prints.

Cost-Efficiency in DTF Printing

The financial benefits of embracing DTF gangsheet builder techniques are significant. By consolidating multiple designs onto one gangsheet, businesses can reduce their film consumption, which directly leads to decreased production costs. This cost-efficiency is particularly advantageous for companies that engage in custom printing or cater to small-batch orders. The ability to capitalize on bulk printing without the need for excessive supplies means savings can also be passed on to customers, making DTF printing an appealing option in a competitive market.

Additionally, the reduction in film usage thanks to gangsheet techniques minimizes waste, contributing to environmental sustainability. As companies increasingly strive to align with eco-friendly practices, utilizing cost-effective printing options like DTF gangsheet building can boost their reputation as sustainable brands. This not only appeals to eco-conscious consumers but also aligns with growing regulations focused on reducing waste and promoting responsible printing practices. Thus, investing in DTF gangsheet techniques isn’t just financially wise; it’s also a step towards fostering a sustainable business model.

Increasing Speed and Efficiency with DTF Techniques

One of the most significant advantages of DTF printing, particularly with gangsheet builder techniques, is the speed at which designs can be produced. By allowing multiple designs to be printed in one go, businesses can significantly reduce turnaround times, which is especially crucial for meeting urgent customer requests or fulfilling high-volume orders. This increased speed not only enhances customer satisfaction but also enables businesses to take on more projects simultaneously, ultimately boosting overall productivity.

Moreover, the efficiency gained from using DTF gangsheet builders leads to smoother operations within a printing business. With less time spent on printing individual designs, staff can focus on other essential aspects of design and production, such as quality control and customer interaction. This results not only in faster lead times but also improves the overall quality of service offered to clients, making DTF printing an attractive option for businesses seeking to scale their operations efficiently.

Sustainable Practices in DTF Printing

As environmental consciousness grows among consumers, the demand for sustainable practices in the DTF printing industry is also rising. Many companies are now exploring eco-friendly materials optioning biodegradable DTF films and environmentally safe inks without compromising on quality. These sustainable DTF techniques align with the global movement towards responsible consumption and production, reflecting positively on brands that adopt them. Companies that incorporate sustainable practices into their operation not only meet customer expectations but also adhere to emerging policies aimed at reducing waste in the printing industry.

Incorporating sustainability into DTF printing involves not just material choices but also production methods. Effective use of DTF gangsheet builder techniques can lead to less waste during the printing process, as multiple designs are printed together on a single sheet. This thoughtful approach not only conserves resources but also reinforces a brand’s commitment to sustainability. As more consumers become environmentally conscious, businesses that prioritize sustainable practices are likely to foster stronger customer loyalty and differentiate themselves in a crowded market.

Leveraging Software for Efficient Gangsheet Building

The integration of technology into the DTF printing process is dramatically enhancing efficiency, particularly through the use of specialized design software. Software solutions optimized for gangsheet building allow designers to create and adjust layouts swiftly, ensuring that all elements are aligned correctly before printing. This integration streamlines workflows by reducing the time and effort needed for manual adjustments while minimizing errors that may arise during the design stage. As software continues to evolve, its impact on the DTF printing process becomes increasingly pronounced.

Moreover, leveraging technology aids in better color management and file organization, crucial aspects for achieving high-quality results with DTF printing. Advanced software tools provide accurate color profiles and can simulate how designs will look once printed, allowing for adjustments before the gangsheet is finalized. This capability not only saves material costs but also enhances the overall quality of the printed designs, ensuring that customer expectations are consistently met and exceeded. With these technological advancements, businesses can streamline their DTF printing processes while showcasing their creative talents effectively.

Frequently Asked Questions

What are the benefits of using DTF gangsheet builder techniques in Direct-to-Film printing?

DTF gangsheet builder techniques significantly enhance production by allowing multiple designs to be printed simultaneously on a single film, resulting in cost-effective printing. These techniques streamline the process, save time, and maximize material usage while maintaining high print quality, making them an essential method for businesses in the DTF printing industry.

How can gangsheet design optimization improve the efficiency of DTF printing?

Gangsheet design optimization improves DTF printing efficiency by strategically placing multiple designs on one transfer film, minimizing waste. This technique reduces film usage and printing time, allowing for faster production rates while ensuring that designs are printed with precision and vivid colors.

What role does color management play in DTF gangsheet builder techniques?

Color management is crucial in DTF gangsheet builder techniques as it ensures that colors are consistent and reflective of the desired outcomes across multiple designs on the gangsheet. By using suitable color profiles for DTF printing, designers can achieve high-quality prints that meet client expectations.

Can DTF printing techniques be considered sustainable, and what methods support this?

Yes, DTF printing techniques can be sustainable, especially with the adoption of eco-friendly DTF materials, such as biodegradable films. Implementing sustainable DTF techniques helps in reducing environmental impact while still achieving high-quality and durable prints, aligning business practices with consumer demand for sustainability.

How does understanding printer capabilities enhance DTF gangsheet building?

Familiarity with a DTF printer’s capabilities is essential for optimizing gangsheet building. Knowing the machine’s specifications allows for appropriate adjustments to settings, ensuring that print quality is maximized, designs are accurately rendered, and overall production efficiency is improved.

What software tools are helpful for implementing DTF gangsheet builder techniques?

Graphic design software like Adobe Illustrator is beneficial for implementing DTF gangsheet builder techniques. These tools help in effective layout planning and design placement, enabling users to optimize space on gang sheets while maintaining precision and high-quality outcomes in DTF printing.

| Key Points | Details |

|---|---|

| Introduction to DTF Printing | DTF printing allows for vibrant designs on various materials using transfer films. |

| What is a DTF Gangsheet? | A large transfer film with multiple designs, optimizing production and reducing costs. |

| Benefits of DTF Gangsheet Techniques | Cost efficiency, increased speed, superior quality, and versatile design placement. |

| Effective Gangsheet Building Techniques | Optimal design placement, color management, material selection, and understanding printer capabilities. |

| Emerging Trends | Sustainability and software integration for enhanced efficiency. |

| Community Resources | Forums and platforms for sharing knowledge and skills related to DTF printing. |

Summary

DTF gangsheet builder techniques provide a transformative approach to enhancing design production in the textile printing industry. By implementing these techniques, designers can achieve significant cost savings, improved speed, and superior print quality. Understanding the nuances of DTF printing, such as optimal design placement and effective material selection, enables businesses to maximize efficiency and meet customer demands more effectively. As the industry evolves, leveraging these advanced techniques will not only enhance design outcomes but also position businesses favorably in a competitive market.