DTF printing techniques are transforming the landscape of textile printing, offering a fresh and efficient way to apply vivid designs onto various fabrics. This innovative method stands out due to its remarkable versatility and durability, making it an attractive option compared to more traditional processes like screen printing and direct-to-garment printing. In this comprehensive guide, you will discover valuable DTF printing tips that can elevate your results, along with an in-depth look at the DTF printing process. Understanding the necessary DTF printing equipment and optimal DTF printing settings is crucial to mastering this technique. Whether you’re a novice or an experienced printer, this post will equip you with the knowledge needed to achieve stunning, professional-quality prints.

Delving into the realm of Direct to Film printing reveals an exciting array of possibilities for custom textile applications. This cutting-edge approach utilizes innovative methods to transfer intricate designs directly onto fabrics, utilizing heat and pressure efficiently. As the popularity of this technique grows, many enthusiasts are eager to learn about effective DTF printing strategies, necessary equipment, and the precise adjustments required for optimal results. With the right preparation and an understanding of the entire printing process, anyone can harness the power of fabric printing and create vibrant, long-lasting designs. Explore the world of DTF printing further to unlock a new level of creativity and craftsmanship in custom garment production.

Understanding the DTF Printing Process

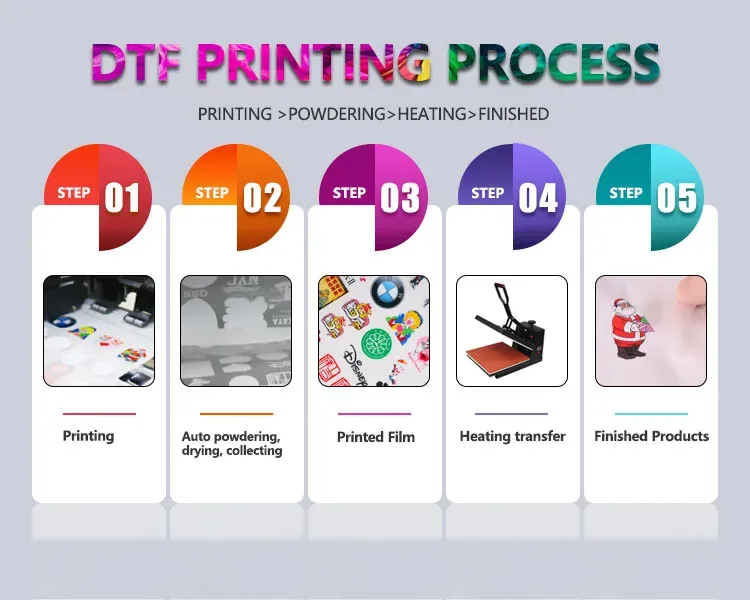

The DTF printing process is a sophisticated technology that involves multiple crucial steps to achieve high-quality designs on fabrics. Initially, the design is printed onto a specialized DTF film using an inkjet printer equipped with DTF inks. This film then undergoes a dusting process where an adhesive powder is applied, ensuring that it sticks to the fabric during the transfer. The final step involves heat pressing the film onto the fabric, where heat and pressure activate the adhesive and bond the design to the material, producing stunning results.

One of the key advantages of the DTF printing process is its ability to print high-resolution images on a wide variety of fabrics, including cotton, polyester, and even blends. This versatility makes it ideal for custom apparel, maintaining color vibrancy and durability even after multiple washes. Moreover, the DTF printing technique eliminates the need for screen printing screens or expensive setup costs typically associated with traditional printing methods, making it not only a cost-effective choice but also an efficient one.

Essential DTF Printing Equipment

To achieve the best results in DTF printing, it’s essential to invest in the right DTF printing equipment. A high-quality printer, preferably one that is compatible with DTF inks, is crucial for creating detailed and vibrant designs. Brands like Epson and Mimaki are known for their performance in this field. Additionally, a reliable heat press machine is vital; it must evenly distribute heat and pressure to ensure proper adhesive transfer. Without the right equipment, achieving high-quality prints can be greatly hampered.

Apart from the printer and heat press, selecting the correct DTF film is equally important. There are various types of films available, such as glossy and matte finishes, which can dramatically affect the final aesthetic of the printed product. Matte films tend to offer a more subdued look, while glossy films enhance color vibrancy and appeal. Taking the time to test different types of film will help you determine which best complements your design approach, leading to stunning final products.

Optimizing DTF Printing Settings for Best Results

Optimizing DTF printing settings is crucial for achieving high-quality prints that truly stand out. Key setting adjustments include resolution, which should be set at a minimum of 1200 DPI to capture fine details effectively. Additionally, proper use of color profiles tailored to the specific ink and fabric type is essential for producing accurate color outputs that match your design intentions. Testing various settings is invaluable, as this can make a significant difference in the vibrancy and accuracy of your final prints.

Also, consider temperature and pressure settings during the heat press process. These determine how well the ink adheres to the fabric. For instance, different fabrics may require specific temperature adjustments; too low may lead to peeling, while too high can damage the design or fabric. By fine-tuning these settings based on fabric type and design complexity, you can significantly enhance the quality and durability of your DTF prints, ensuring they not only look great but also stand the test of time in everyday use.

Pre-Press and Post-Press Considerations

Preparing fabric for DTF printing is a critical step that can impact the quality of the final product. Pre-press preparation involves thoroughly cleaning the fabric to remove any oils or debris that could affect the adhesion of the print. For synthetic materials like polyester, pre-treating is often necessary to enhance ink adherence. Skipping these steps can result in poor-quality prints, with issues such as incomplete transfers or peeling designs that compromise the overall appearance.

Post-press processes are equally important; curing the printed designs helps set the ink permanently on the fabric. Some printers may require a secondary heat pressing step to ensure the design is fully adhered and durable. Additionally, it’s important to handle the fabric carefully immediately after pressing to prevent stretching or damaging the design. By following these pre-press and post-press considerations, you help guarantee that your DTF prints achieve optimal durability and aesthetic appeal.

Troubleshooting Common DTF Printing Issues

Even experienced printers may encounter common challenges when using DTF printing techniques. Ink smudging is one such issue often attributable to incorrect pressure or temperature during the heat press process. To mitigate this, it’s essential to experiment with different settings based on the specific fabric used. Regularly checking and calibrating your heat press can greatly reduce these types of problems, ensuring that the quality of your prints remains high.

Another frequent issue faced in DTF printing is design peeling. This can occur if the film is not properly adhered to the fabric during pressing. To avoid this, ensure that adequate heat and pressure are applied during the transfer process. Conducting tests on sample fabrics before starting a larger production run can help identify the optimal settings and prevent these common pitfalls. By understanding these troubleshooting techniques, you can improve your DTF printing outcomes and achieve stunning results.

Tips for Mastering DTF Printing Techniques

Mastering DTF printing techniques requires practice, experimentation, and a commitment to learning. One effective way to improve your skills is by regularly testing out new designs and materials. This approach not only enhances familiarity with different settings and equipment but also inspires creativity and innovation in your printing projects. Documenting your experiments will assist in fine-tuning your processes and identifying what works best for specific designs and fabric types.

Also, staying informed about the latest developments in DTF printing technology and trends can provide a competitive advantage. Joining online forums, participating in workshops, and reading industry publications can connect you with other professionals and expand your knowledge base. These interactions can offer invaluable insights into best practices and emerging tools that can elevate your DTF printing capabilities, ultimately leading to improved results and client satisfaction.

Frequently Asked Questions

What are the essential DTF printing tips for beginners?

For beginners in DTF printing, it’s crucial to focus on the right equipment, such as a quality DTF printer and heat press machine. Additionally, ensure to select the correct DTF film that suits your projects and practice adjusting the printing settings to achieve the best results. Finally, always clean and pre-treat your fabric for optimal ink adhesion.

How does the DTF printing process work?

The DTF printing process involves printing your design onto a special film, applying a heat-activated adhesive powder, and then heat-pressing this film onto the fabric. This method allows for vibrant and durable prints on various materials, providing an innovative alternative to traditional printing techniques.

What DTF printing equipment do I need to get started?

To get started with DTF printing, you’ll need a reliable DTF printer that supports water-based inks, a high-quality heat press for transferring designs, and specific DTF films. Additionally, having a clean workspace and essential tools for pre-press preparation will enhance your printing outcomes.

How can I optimize my DTF printing settings for better results?

To optimize DTF printing settings, adjust your printer’s resolution to at least 1200 DPI for detailed graphics and select the appropriate color profiles. Frequent testing of your settings based on fabric types will help ensure color accuracy and vibrant prints. Always monitor the temperature and pressure during the heat pressing stage.

What common challenges can occur in DTF printing, and how can I troubleshoot them?

Common challenges in DTF printing include ink smudging and design peeling. Ink smudging often results from incorrect temperature settings during heat pressing, while peeling may occur from inadequate adhesion. To troubleshoot, adjust the pressure and temperature accordingly and ensure proper pre-treatment of fabrics.

What are some key DTF printing tips for maximizing design durability?

To maximize the durability of your DTF prints, first, ensure proper curing of the prints post-pressing. Avoid stretching the fabric too soon after the heat transfer to maintain the integrity of the design. Regular maintenance of your DTF printing equipment also contributes to long-lasting results.

| Key Point | Description |

|---|---|

| Introduction to DTF Printing | DTF printing revolutionizes textile printing with high-quality designs on various fabrics. |

| Key Components | Includes film, high-quality inks, and the printing process that uses heat and pressure. |

| Printing Tips | Focus on choosing the right printer, preparing fabrics, optimizing settings, and post-press care. |

| Troubleshooting | Be aware of common challenges like ink smudging and design peeling, with tips to resolve them. |

| Conclusion | Mastering DTF printing techniques enhances the quality and creativity of printed fabrics. |

Summary

DTF printing techniques have emerged as a transformative force in fabric printing, enabling creators to produce vibrant and durable designs on various textiles. This innovative technique not only simplifies the printing process but also enhances the versatility that many businesses seek in custom apparel. By incorporating specific tips regarding equipment selection, preparation of materials, and adherence to optimal printing settings, anyone can achieve remarkable results in their DTF printing endeavors. With practice and experimentation, individuals can refine their skills and explore new creative avenues, making DTF printing a valuable asset in any textile printing operation.