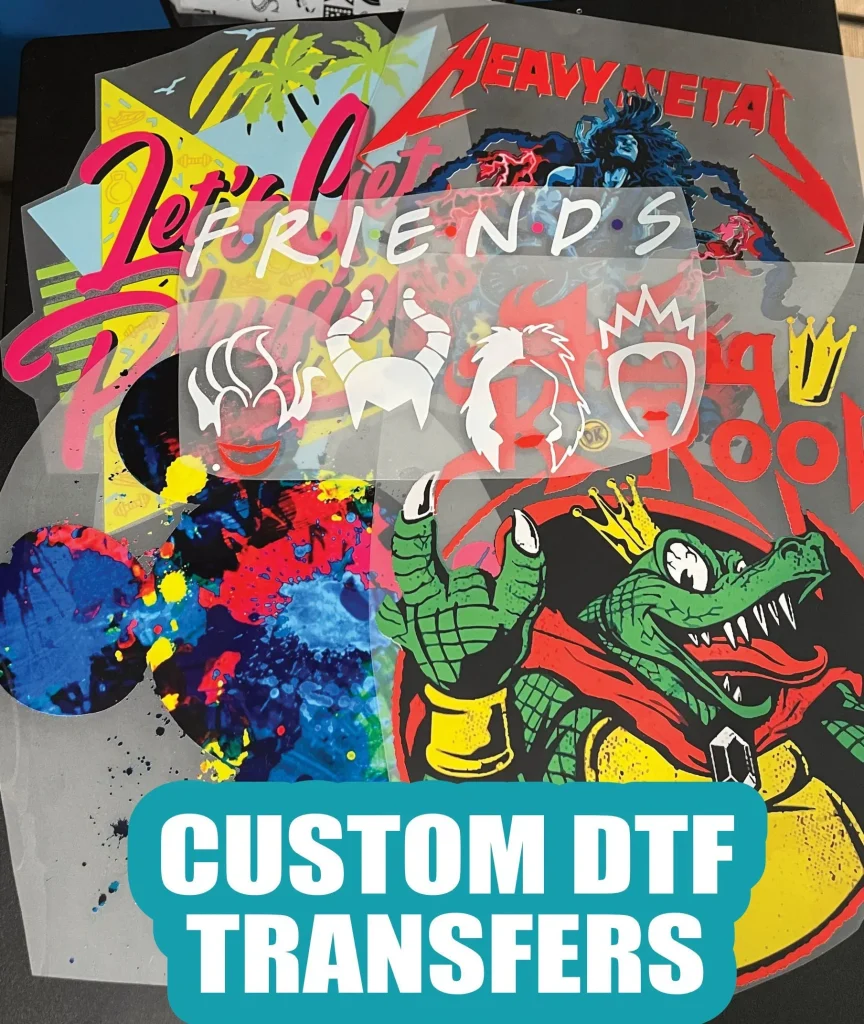

In the realm of customized apparel, DTF transfers are rapidly gaining attention as a game-changing technology. Unlike traditional printing methods such as screen printing and direct-to-garment (DTG) that have dominated the market, DTF printing offers a plethora of advantages that appeal to modern businesses. With its ability to produce vibrant colors and intricate designs on a variety of materials, it’s no wonder that many are asking about the cost of DTF printing compared to its counterparts. This innovative technique combines speed, flexibility, and quality in a way that helps businesses meet diverse customer needs quickly and efficiently. As we explore the many facets of DTF printing advantages, you’ll discover why it might just be the ideal choice for your next project.

When looking into the world of apparel printing, Direct-to-Film (DTF) techniques are revolutionizing how designs are transferred onto fabrics. This modern approach can often overshadow conventional methods like screen printing or digital garment printing, appealing to industries seeking rapid production and customization. DTF printing not only stands out for its cost effectiveness in smaller runs but also boasts significant versatility across various garment types. If you’re considering your options, understanding the strengths and limitations of both DTF and older methods will guide your decision-making process effectively. As the printing landscape evolves, recognizing these crucial alternatives can lead to more informed choices and ultimately enhance your business offerings.

1. Exploring the Evolution of Printing Technologies

The field of printing has seen a significant evolution over the decades, moving from traditional methods like screen printing to advanced technologies such as Direct-to-Film (DTF) printing. Screen printing, although still widely used, has limitations in terms of color complexity and production speed, especially for small batches. DTF printing emerged as a response to these challenges, allowing for the application of intricate designs with a rapid turnaround time. This shift underscores the textile industry’s ongoing quest for innovation and efficiency.

In addition, the versatility of DTF printing allows businesses to cater to a broader audience by handling a variety of fabric types such as cotton, polyester, and blends. This has opened new avenues for customized apparel that were previously constrained by the limitations of traditional printing methods. The adaptability of DTF technology demonstrates how modern techniques are reshaping custom print offerings in ways that align better with consumer demands.

2. DTF Transfers vs. Screen Printing: A Comparative Approach

When comparing DTF transfers to traditional screen printing, it’s crucial to consider factors such as cost, quality, and production capacity. DTF printing is often favored for small and medium order sizes, primarily due to its lower initial investment compared to the expensive setups required for screen printing. Additionally, DTF technology provides unparalleled detail and color accuracy, making it ideal for complex designs that screen printing may struggle to replicate.

On the other hand, screen printing thrives in high-volume production wherein the setup costs are amortized over large orders, creating a cost advantage. While its durability and vibrant color output on cotton fabric are noteworthy, the need for multiple screens for varied colors can slow down the process for intricate designs. Therefore, businesses must weigh their needs against these different strengths to determine the most suitable method.

3. The Benefits of DTF Printing for Small Businesses

For small businesses or individuals looking to enter the custom apparel market, DTF printing provides several advantages over traditional methods. One significant benefit is the ability to create diverse designs without the excessive costs associated with traditional screen printing setups. With DTF technology, entrepreneurs can produce high-quality prints on-demand, allowing them to test various ideas without a hefty financial risk.

Moreover, the speed and efficiency of DTF printing mean that businesses can pivot quickly to current trends or individual client requests. This flexibility is essential in a fast-moving market where customer preferences can shift rapidly. As such, small businesses can thrive by leveraging DTF printing’s capabilities to offer personalized products while maintaining lower overhead costs.

4. Evaluating Durability and Quality in DTF And Traditional Methods

Durability is a critical factor when choosing between DTF transfers and traditional printing options. DTF printing is designed to maintain impressive durability and wash resistance, often outperforming direct-to-garment prints in longevity. By utilizing high-quality films and adhesives, DTF prints withstand regular use while retaining their vibrant colors, making them suitable for garments that require frequent washing and wear.

In contrast, while screen printing offers excellent durability, especially on cotton fabrics, it may not perform as well on synthetic blends, which can lead to fading over time. Therefore, businesses must consider the specific fabrics they intend to use and how often the garments will be worn. By understanding the durability factors of each printing method, businesses can ensure they provide quality products that meet their customers’ expectations.

5. Cost Analysis of DTF Printing vs. Traditional Techniques

One of the most significant considerations in selecting a printing method is the overall cost. DTF printing tends to present a lower upfront cost for small batches due to reduced setup time and equipment expenses compared to traditional screen printing. This is particularly advantageous for businesses focusing on custom orders, where flexibility and the ability to manage small quantities economically are essential.

Conversely, as order sizes increase, screen printing typically becomes more cost-effective due to lower per-unit costs after initial set-up. For larger production runs, businesses may find screen printing a more economical choice. Evaluating the total costs associated with each method—considering both fixed and variable expenses—enables businesses to make informed decisions that align with their financial strategies.

6. Future Trends in Customized Apparel Printing

As the demand for personalized apparel grows, the future of printing technologies like DTF appears bright. Innovations continue to emerge, enhancing the speed, quality, and versatility of printing processes. Businesses are increasingly adopting DTF printing to meet consumer preferences for unique, high-quality products without the lengthy production times associated with traditional methods.

Furthermore, advancements in ink technology and printing machinery are expected to further enhance the efficiency of DTF printing, allowing for larger scale production without compromising on quality. The future of apparel printing is likely to be characterized by continued integration of technology, customization, and sustainability, shaping an exciting landscape for both businesses and consumers.

Frequently Asked Questions

What are the main differences between DTF transfers and traditional printing methods like screen printing?

DTF transfers stand out from traditional printing methods such as screen printing by offering vibrant color reproduction and the ability to print intricate designs with ease. While screen printing is cost-effective for large batches, DTF excels in flexibility, quality, and speed for small orders, making it modern and efficient for custom projects.

How does DTF printing compare in quality to direct-to-garment (DTG) printing?

Quality-wise, DTF printing often surpasses direct-to-garment (DTG) printing when it comes to vibrant colors and fine details. DTF supports multiple colors effortlessly, making it ideal for complex designs, whereas DTG may experience slower production speeds for larger orders. Therefore, for high-quality, detailed prints, DTF is a preferred choice.

Is DTF printing more cost-effective than traditional screen printing methods?

DTF printing can be more cost-effective for small batches or custom jobs compared to traditional screen printing, which requires costly setups for initial runs. However, as print volumes increase, screen printing becomes more favorable in terms of cost per unit. It’s essential to evaluate your printing needs to determine the most cost-effective method.

What advantages does DTF printing offer concerning material compatibility versus traditional methods?

One key advantage of DTF printing is its compatibility with a wide variety of fabrics, including cotton, polyester, and blends. In contrast, traditional methods like screen printing mainly perform best on cotton. DTF’s versatility allows for a broader range of products without compromising print quality, catering to diverse merchandising needs.

How durable are DTF prints compared to screen printing and DTG prints?

DTF prints are known for their high durability, making them resistant to wear and tear with regular washing. While screen printing is highly durable, particularly on cotton fabrics, DTG prints may fade over time if not cared for properly. Overall, DTF provides a strong option for long-lasting prints suitable for everyday use.

What are the production speed advantages of DTF transfers over traditional printing methods?

One of the major advantages of DTF transfers is their rapid production speed, which allows businesses to fulfill small order runs efficiently without compromising quality. Traditional printing methods like screen printing are faster for consistent designs but require lengthy setups for new designs, making DTF more flexible for varied and custom projects.

| Aspect | DTF Printing | Traditional Printing |

|---|---|---|

| Quality and Precision | Produces vibrant colors and intricate designs, handles multiple colors easily. | Good for vibrant prints but struggles with very intricate designs. DTG offers detail but is slower. |

| Cost-Effectiveness | Lower upfront costs for small batches, higher cost per print for large quantities. | More cost-effective for large volumes after initial setup. |

| Production Speed and Efficiency | Fast production for small runs; maintains quality. | Faster for large orders; variable designs require new setups, making it slower. |

| Material Compatibility | Compatible with various fabrics (cotton, polyester, blends). | Optimized for cotton; DTG requires pretreatment for some fabrics. |

| Durability | Remarkable durability generally holds up well. | Known for excellent durability, while DTG may fade if not cared for. |

Summary

DTF transfers represent a significant advancement in the realm of custom apparel printing, offering businesses a modern and effective solution to their printing needs. With the ability to produce high-quality designs quickly, as well as their compatibility with various fabric types, DTF printing is an appealing choice for both small and large operations alike. Its cost-effectiveness and durability further enhance its appeal, making it a preferred option for many entrepreneurs. Understanding the differences between DTF transfers and traditional methods empowers businesses to make informed decisions aligned with their specific needs and project requirements.