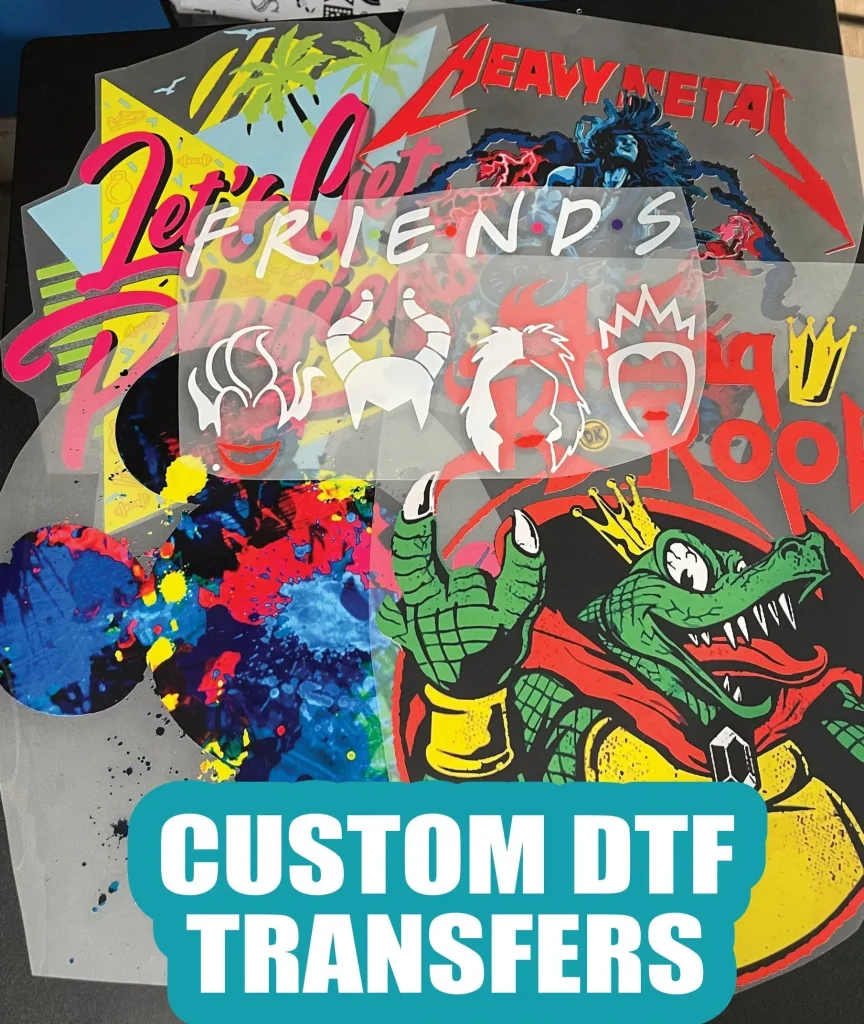

In the dynamic realm of custom apparel, DTF transfers, or Direct-to-Film transfers, have revolutionized the way designs are applied to fabrics. This innovative printing method allows for the creation of vibrant fabric prints that are both eye-catching and durable, making them a top choice among apparel designers. Whether you’re crafting a bold graphic tee or unique promotional merchandise, understanding the DTF transfer process can significantly enhance your custom apparel design capabilities. As we venture into this comprehensive guide, we’ll unveil essential tips and techniques that will help you harness the full potential of DTF transfers, showcasing the artistry that goes into every vibrant print. Join us as we explore the ins and outs of this exciting technique and how it can elevate your design projects.

Also referred to as Direct-to-Film printing, DTF transfers offer an innovative solution for designers looking to create high-quality fabric prints. This cutting-edge technique combines the advantages of traditional heat transfer methods with the precision of modern digital printing, allowing for detailed and colorful designs that truly stand out. From custom clothing items to promotional goods, the versatility of DTF printing makes it a popular option for many creators in the fashion industry. Throughout this article, we will discuss the DTF design tips necessary to ensure your prints retain their vibrancy and durability, all while providing a step-by-step approach to mastering this contemporary printing method. Prepare to dive deeper into the world of Direct-to-Film applications and discover how they can transform your creative endeavors.

Understanding the DTF Transfer Process

The Direct-to-Film (DTF) transfer process is an innovative method that fundamentally changes how designers approach the realm of custom apparel. At its core, DTF involves printing designs onto a special film before applying them to fabrics, creating a bridge between digital artistry and textile printing. This process starts with choosing high-resolution graphics in the CMYK color mode, ensuring that every detail is captured vividly when transferred onto the fabric. A compatible inkjet printer is crucial for this stage, as traditional screen printing methods can limit the intricacies that DTF can achieve.

Once your design has been printed onto the film in reverse, the application of adhesive powder is a pivotal step. This adhesive is specifically formulated for DTF inks, allowing for a flawless bond between the design and the fabric during the transfer. After evenly sprinkling the powder and curing it with heat, you can move on to the heat transfer, where the design bonds itself to the fabric at optimal temperatures. Understanding each step and ensuring precision throughout the DTF transfer process is key to producing stunning, long-lasting prints.

Advantages of Using DTF Transfers in Custom Apparel Design

One of the standout benefits of DTF transfers is their versatility across a variety of materials. This method works seamlessly on cotton, polyester, and blends, providing designers with a broader scope for customization in apparel. Unlike traditional screen printing, which often requires different setups for different materials, DTF saves time and unit costs while delivering vivid fabric prints. This adaptability not only expands the range of products you can offer but also enhances creativity in custom apparel design.

Moreover, DTF transfers produce exceptionally vibrant colors that remain bright and intact through numerous washes, making them an ideal choice for promotional items and apparel used frequently. The durability of DTF prints ensures that your designs maintain their appearance over time, satisfying customers and fostering brand loyalty. Whether you’re creating team jerseys or unique fashion statements, DTF transfers provide a reliable option for designers looking to make a strong impact.

Step-by-Step Guide to Mastering DTF Transfers

To master DTF transfers, designers must follow a systematic approach that begins with design creation. Using design software allows for the manipulation and enhancement of graphics, ensuring they are not only visually appealing but also optimized for printing. Ensuring high-resolution files and understanding color profiles are foundational steps. Making initial drafts is encouraged, allowing you to experiment with designs and determine what works best, especially if you’re planning to feature intricate graphics, as these are part of the allure of custom apparel.

The success of DTF transfers hinges on meticulous attention to detail through each step of the process. This includes everything from selecting the right printer and applying the adhesive powder to transferring the design onto the fabric under controlled conditions. Familiarization with heat press settings is crucial, and testing these on fabric scraps can prevent costly mistakes. By adhering to a structured approach, designers can optimize their workflow and ensure the best possible outcomes for vibrant, eye-catching fabric prints.

Essential DTF Design Tips for Vibrant Fabric Prints

Creating vibrant fabric prints with DTF transfers requires more than just the right equipment; it also involves creativity and strategic design considerations. One essential tip is to select colors wisely, with a focus on those that will stand out once printed on fabric. Testing your color choices on different materials can reveal how colors interact with the fabric’s base hue. Additionally, take advantage of high-contrast designs that can pop against the fabric backdrop, ensuring that even intricate details are visible from a distance.

Moreover, leaving adequate spacing between elements in your designs can enhance their visibility and impact when transferred. It’s also important to optimize your design for the fabric type—what works for cotton may not translate perfectly onto synthetic blends. Considering these design tips facilitates not only mandatory attention to aesthetic appeal but also improves the functionality and longevity of each custom piece, paving the way for successful branding and customer retention.

Maintaining Equipment for Optimal DTF Transfer Results

Regular maintenance of your printing equipment is paramount to achieving consistent and high-quality DTF transfers. Over time, inkjet printers can accumulate clogs and buildups that hinder the printing process. To prevent such issues, regularly check and clean your printer heads and nozzles, and use high-quality inks that are specifically formulated for DTF printing. This ensures smoother operation and less downtime, allowing you to fulfill orders promptly and reliably.

In addition to printer upkeep, selecting appropriate transfer films can significantly influence the outcome of your DTF transfers. Investing in high-grade films specifically designed for use with your printer type ensures better adhesion and higher print quality. Storing these materials properly—keeping them in cool, dry places—will also extend their lifespan and effectiveness, contributing to the successful creation of vibrant, durable designs on your custom apparel.

The Future of Custom Apparel: DTF Transfers and Beyond

As the apparel industry continues to evolve, DTF transfers stand at the forefront of innovation in custom design. Their ability to produce vibrant, detailed prints on a variety of fabrics has made them increasingly popular among designers and businesses looking to make a mark. Moving forward, advancements in printing technology, inks, and materials will further enhance the capabilities of DTF transfers, making it easier to breathe life into creative concepts. This is an exciting time for designers who wish to adopt cutting-edge methods to serve an ever-growing market.

Moreover, as sustainability becomes a priority in the fashion industry, DTF transfers can offer an environmentally friendly alternative to traditional methods. By minimizing waste and maximizing efficiency, DTF enables designers to reduce their carbon footprint while still achieving high-quality results. As designers explore these possibilities, the future looks promising, with DTF transfers paving the way for innovative approaches to custom apparel design.

Frequently Asked Questions

What is the DTF transfer process and how does it work?

The DTF transfer process involves printing designs onto a special film using Direct-to-Film technology. This technique allows you to create vibrant fabric prints by applying heat to transfer the design onto various materials, such as cotton or polyester. The DTF process combines the clarity of digital printing with the durability of heat transfers.

What are the benefits of using DTF transfers for custom apparel design?

DTF transfers are highly advantageous for custom apparel design due to their versatility, vibrant colors, and ability to reproduce intricate details. They work on different fabric types and maintain their vividness even after multiple washes, ensuring your designs look great over time.

How can I create high-quality designs for DTF transfers?

To create high-quality designs for DTF transfers, use graphic design software and ensure your artwork is in high resolution with CMYK color mode. This approach helps produce rich, vibrant fabric prints that are perfect for the DTF transfer process.

What materials can I use with DTF transfers?

DTF transfers are compatible with a wide variety of materials, including cotton, polyester, and fabric blends. This versatility makes them an excellent choice for custom apparel design across multiple product categories.

What are some key DTF design tips for success?

For successful DTF transfers, maintain your printer for optimal performance, use high-quality DTF transfer films, and always test heat settings before applying your design to the final garment. Careful preparation will enhance the quality and longevity of your vibrant fabric prints.

Are DTF transfers durable compared to other printing methods?

Yes, DTF transfers are known for their durability. They provide excellent resistance to washing and wear, maintaining the integrity of vibrant fabric prints over time, which makes them a popular choice for custom apparel among designers.

| Key Point | Details |

|---|---|

| What are DTF Transfers? | A modern printing technique that prints designs on a special film for transfer to fabrics using heat. |

| Advantages of DTF Transfers | 1. Versatile across materials 2. Bright colors 3. High detail reproduction 4. Durable after multiple washes |

| Step 1: Design Creation | Use graphic software to create high-resolution designs in CMYK color mode. |

| Step 2: Printing the Design | Print in reverse with a compatible inkjet printer. |

| Step 3: Applying Adhesive Powder | Sprinkle and cure the adhesive powder over printed design. |

| Step 4: Transfer to Fabric | Use a heat press to transfer the design onto the fabric for specified time and temperature. |

| Step 5: Cooling and Peeling | Let it cool and then peel off the film to reveal the design. |

| Tips for Successful DTF Transfers | 1. Maintain your printer 2. Use high-grade films 3. Test heat settings 4. Store films correctly |

Summary

DTF Transfers are revolutionizing the custom apparel industry, allowing creators to produce vibrant, detailed designs that are both versatile and durable. This innovative printing technique accommodates various fabrics and withstands the rigors of wear and washing, making it essential for designers aiming to deliver high-quality products. By mastering the DTF process, whether through careful design creation or proper application techniques, designers can significantly enhance their offerings, making their work stand out in a competitive marketplace.