DTF transfers, or Direct-to-Film transfers, are revolutionizing the custom garment printing landscape, particularly for small businesses looking to maximize their efficiency and profitability. This innovative printing method not only allows for vibrant and detailed designs but also presents a cost-effective alternative to traditional printing processes. With a focus on affordability, DTF transfers have become a popular choice among entrepreneurs seeking to enter the competitive world of custom apparel. Analyzing key factors such as production speed, material costs, and overall DTF printing benefits can provide invaluable insights for small businesses aiming to thrive. As we explore the intricacies of this technology, it becomes clear that understanding DTF printing costs and advantages will be essential for those looking to elevate their printing ventures.

The emergence of Direct-to-Film technology signifies a transformative phase in the printing industry, specifically for businesses specializing in personalized clothing. As printers and designers seek efficient solutions, alternatives such as film-based transfer methods are garnering attention for their versatility and ease of use. With numerous advantages in production cost and speed, employing these transfer techniques offers a promising route for custom apparel ventures. This article will dive into the benefits of such printing methods, exploring how they align with the specific needs of small business operations focused on garment customization. Delving deeper into these alternative printing solutions will illustrate their potential to reshape successful business strategies.

The Rise of DTF Transfers in Custom Printing

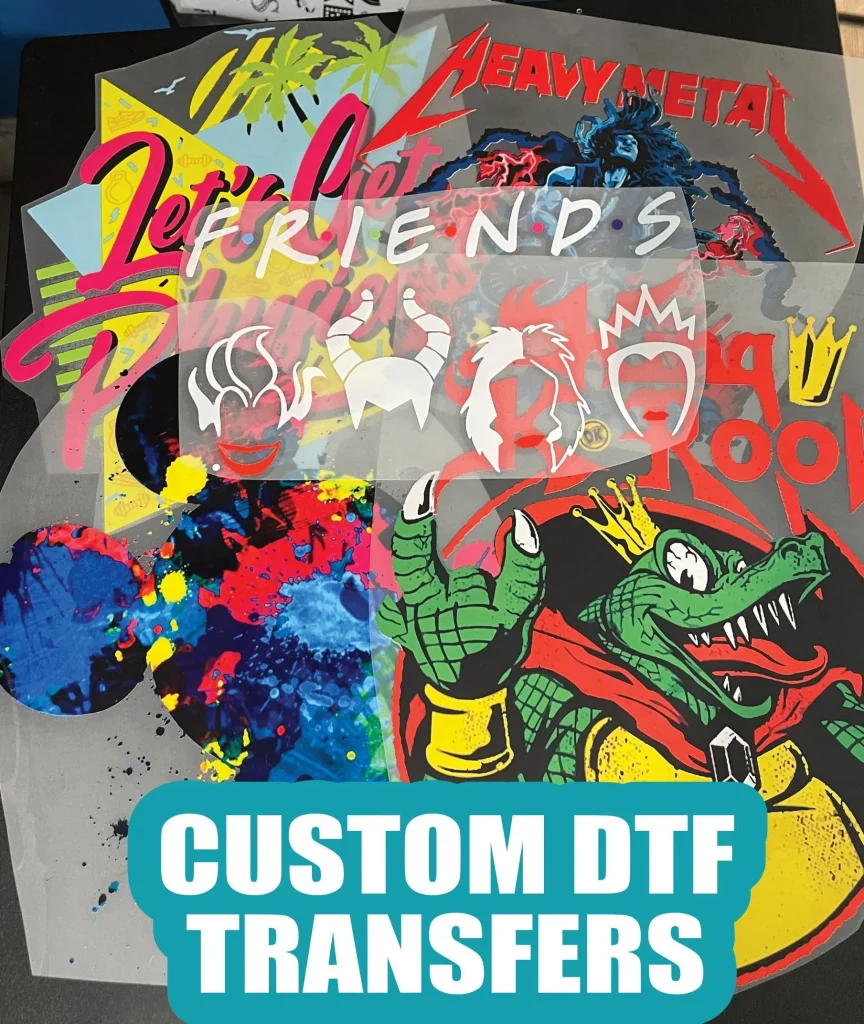

In the world of custom garment printing, Direct-to-Film (DTF) transfers have quickly gained popularity due to their remarkable efficiency and versatility. This innovative printing method allows for vibrant, high-resolution designs to be printed on a variety of fabrics, making it increasingly appealing to small business owners. With the ability to produce detailed and complex designs without the limitations of traditional methods, DTF transfers present an exciting opportunity to cater to diverse customer preferences.

As we analyze the trends in small business printing, it becomes clear that the affordability of DTF transfers is contributing to their rapid adoption. By reducing the need for extensive setup time and costly materials, DTF is enabling businesses to streamline their operations and maximize their profitability. Moreover, with the growing demand for personalized apparel, small businesses can leverage DTF technology to offer unique products that resonate with their customers.

Frequently Asked Questions

What are the cost-effective printing benefits of DTF transfers for small businesses?

DTF transfers offer significant cost-effective printing benefits for small businesses, making them an ideal choice for custom garment printing. They require lower startup costs compared to traditional methods like screen printing, with complete setups costing between $5,000 to $10,000. Additionally, DTF printing involves reduced material costs and labor expenses, leading to higher profit margins and significant savings over time.

How do DTF printing costs compare to traditional printing methods?

When comparing DTF printing costs to traditional methods such as screen printing and Direct-to-Garment (DTG), DTF often emerges as the more budget-friendly option. Traditional setups typically incur higher initial investments and maintenance costs, while DTF allows for cost-effective operations due to lower material costs and reduced labor needs, thus increasing the profitability for small businesses.

Why should small businesses consider DTF printing for custom garment printing?

Small businesses should consider DTF printing for custom garment printing due to its versatility, high-quality output, and cost efficiency. DTF transfers can create vibrant prints on a variety of fabrics, opening up new markets without the excessive costs associated with other methods. This flexibility enables businesses to cater to a wider audience while maintaining affordability.

What impact does DTF printing have on production speed for small businesses?

DTF printing significantly enhances production speed for small businesses by facilitating rapid production capabilities. With DTF methodology, businesses can achieve faster turnaround times and scale up production volumes without an extensive labor force. This efficiency not only improves workflow but also leads to increased customer satisfaction due to quicker delivery.

Are there environmental considerations with DTF transfers for custom printing?

Yes, there are important environmental considerations with DTF transfers. DTF inks are primarily water-based, making them a safer alternative to traditional inks that may contain harmful chemicals. This eco-friendliness can attract environmentally conscious consumers, giving small businesses a competitive edge in the market while promoting sustainable printing practices.

How can DTF printing help improve profit margins for small print shops?

DTF printing can help improve profit margins for small print shops by lowering production costs and enabling custom on-demand orders. With a potential profit margin of up to 50% as reported in industry studies, businesses leveraging DTF technology can enhance their pricing competitiveness and overall financial performance, making it a strategic investment for growth.

| Aspect | Details |

|---|---|

| Direct-to-Film (DTF) Transfers | Innovative printing method for custom garment printing with vibrant, high-resolution designs. |

| Cost Efficiency | DTF offers lower startup costs compared to screen printing, making it accessible for small businesses. |

| Material Costs | Generally lower than traditional printing methods, enabling premium quality at reduced expenses. |

| Versatility | Can print on diverse materials, appealing to niche markets and broadening customer bases. |

| Profit Margins | Potential profit margins of up to 50%, especially with custom orders. |

| Production Speed | Rapid production capabilities enhance workflow efficiency and customer satisfaction. |

| Environmental Impact | DTF often utilizes water-based inks, presenting a safer alternative to traditional inks. |

Summary

DTF transfers are revolutionizing the custom garment printing industry by offering a cost-effective and versatile solution for small businesses. This innovative printing method not only reduces startup costs and material expenses but also enhances profit margins and production speed. Furthermore, the use of environmentally friendly inks positions DTF as an attractive option for eco-conscious consumers. By leveraging these benefits, small businesses can stay competitive and thrive in a rapidly changing market, making DTF transfers a critical tool for growth and sustainability.