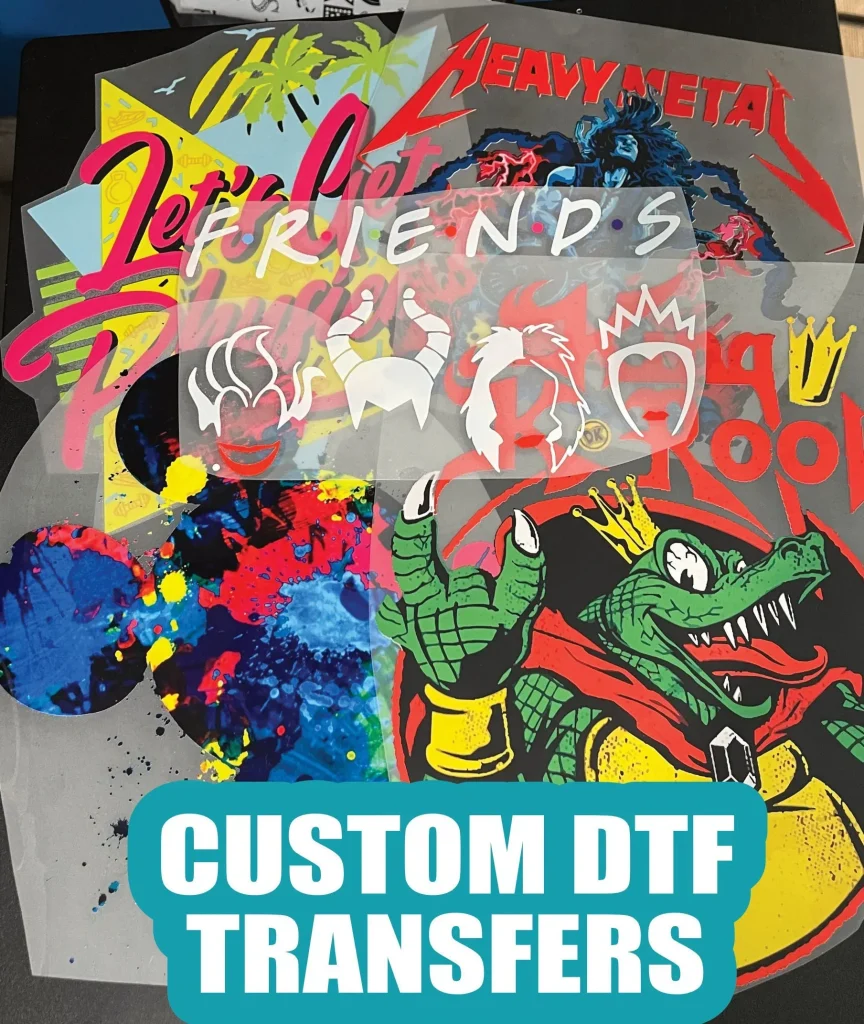

DTF transfers have gained immense popularity, revolutionizing the way designs are applied to textiles. This innovative process enables users to create eye-catching, vibrant prints that are both durable and easy to apply. If you’re looking to master this technique, our guide will provide you with a step-by-step tutorial on how to apply DTF transfers like a pro, focusing on methods for a bubble-free DTF application. From understanding the fundamentals of DTF printing to exploring advanced options like Insta DTF and UVDTF techniques, you will learn everything necessary for success. Dive into the world of DTF transfers, where creativity meets exceptional quality!

Direct to Film (DTF) printing has emerged as a game-changing method in the textile decoration industry, allowing enthusiasts and professionals alike to produce stunning fabric designs effortlessly. Often referred to as DTF application or transfer printing, this method utilizes a specialized film to accurately transfer images onto various fabric types. With its versatility and ease of use, DTF printing has become a go-to choice for both small businesses and individual crafters. Whether you are new to fabric printing or an experienced designer, understanding the DTF process can significantly enhance your creative projects. Join us as we explore the essential techniques and tips for achieving remarkable results with DTF methods.

The Basics of DTF Transfers: What You Need to Know

DTF transfers represent a modern innovation in fabric printing that caters to both hobbyists and corporations alike. Unlike traditional heat transfer methods, DTF transfers utilize a specific film that enables vibrant designs to be transferred to various fabrics such as cotton, polyester, or blends. Understanding the mechanics of this technique is crucial for a successful application, as it involves both printing and pressing stages that must be meticulously executed.

The primary advantage of DTF transfers lies in their versatility and durability. They are designed to provide a strong adhesion that withstands regular washing and wear, which is a significant benefit for personalized apparel and custom merchandise. This method reduces the likelihood of fading and cracking over time, ensuring that your designs maintain their integrity and vibrancy, even under harsh use.

Key Materials for a Successful DTF Application

To achieve great results with DTF transfers, gathering the right materials is crucial. The essential items you need include DTF transfer sheets, a reliable heat press or iron, and a Teflon sheet for added protection during the heat application process. Other helpful tools comprise scissors or a cutting machine based on your design requirements, and a firm, heat-resistant surface for effective pressing.

Starting with high-quality DTF transfer sheets is imperative; the quality of your materials significantly influences the final results. Ensure all equipment, especially printers and heat presses, are optimally configured to work seamlessly with DTF processes. By preparing your workspace with these vital materials, you set the stage for successful DTF printing and application that delivers outstanding results.

Step-by-Step Guide to Applying DTF Transfers

Applying DTF transfers effectively combines several steps, each of which must be executed with precision. It begins with preparing the design, ensuring it is tailored for DTF printing. The design, once printed on the special transfer sheets, needs to be allowed to dry adequately to prevent smearing during future applications. Each phase plays a significant role in ensuring that the final product is not just visually appealing but also durable.

Following the printing phase, prepping the fabric is equally essential. Washing and ironing the fabric helps eliminate any dust or creases, leading to better adhesion of the transfer. Once your fabric is laid out flat, you can begin the actual transfer application. It’s critical to center the transfer accurately and ensure appropriate heat and pressure are applied to foster strong bonding between the ink and the fabric.

Error-Proofing Your DTF Transfer Application

One of the considerable concerns when applying DTF transfers is the occurrence of bubbles. To avoid this, it is vital to pay close attention during the pressing phase. Some techniques involve using a Teflon sheet that not only protects the transfer but can also help mitigate bubble formation. Ensuring your transfers are properly cooled can also facilitate a bubble-free finish, as it allows the inks to set adequately.

Additionally, investigating newer application methods such as UVDTF can provide further insights into achieving an impeccable finish. This technique emphasizes careful handling of the film, which directly affects the quality of the output. Incorporating these best practices can guarantee that you’re less likely to encounter issues, leading to a superior DTF application experience.

Innovative Techniques in DTF Transfers for Modern Use

As technology evolves, so do the techniques and products available for DTF transfers. Innovations such as Insta DTF have emerged, promising a more straightforward and efficient application process without sacrificing quality. This product offers a universal solution for heat transfers, making it a favored choice for personalized garments and promotional items.

Moreover, advanced techniques such as UVDTF facilitate intricate designs with a focus on eliminating bubbles and enhancing the application process. By keeping abreast of these innovations, crafters can ensure they are using cutting-edge methods that yield professional-grade results. Adopting these modern advancements leads to a more streamlined workflow, empowering creators to push their design boundaries.

Troubleshooting Common Issues with DTF Transfers

Even with the most careful preparations, issues may arise during the DTF transfer process. A common challenge is uneven adhesion, where certain parts of the design may lift or fail to bond with the fabric properly. When this happens, it is often beneficial to re-apply heat, using a Teflon sheet for protection, focusing particularly on the poorly adhered areas.

Another common issue that users face is the quality of the printed transfer itself. Using low-quality inks or incorrect printer settings can result in subpar designs that don’t hold up under pressure or washing. For best results, always follow the manufacturer’s guidelines regarding ink usage and printer settings tailored for DTF printing.

Frequently Asked Questions

How do I apply DTF transfers effectively?

To apply DTF transfers effectively, start by preparing your fabric and ensuring it is clean and free of creases. Print your design on DTF transfer sheets using a DTF printer, then position the transfer on the fabric. Cover it with a Teflon sheet and apply heat and pressure using a heat press for 15-20 seconds. Allow it to cool slightly before peeling off the backing for a smooth, bubble-free finish.

What materials do I need for DTF printing?

For DTF printing, you’ll need DTF transfer sheets, a compatible DTF printer, a heat press or iron, a Teflon sheet (optional for protection), and a hard, flat surface for applying the transfers. Additionally, having scissors or a cutting machine will help in preparing your designs.

What is the benefit of using Insta DTF for applications?

Insta DTF is a versatile solution for applying DTF transfers that offers ease of use and exceptional quality. It simplifies the process, making it suitable for both beginners and experienced users looking to create custom designs with minimal effort while achieving professional results.

What should I do if my DTF transfer has bubbles?

If your DTF transfer has bubbles, ensure that you are applying proper pressure and temperature during the application. Additionally, using a Teflon sheet can help prevent bubbles. If bubbles appear, you can reapply heat and pressure with the Teflon sheet to help adhere the design better and remove imperfections.

What is the UVDTF technique in DTF printing?

UVDTF (Ultra Vivid Direct to Film) is an advanced DTF printing technique that focuses on producing vibrant colors and bubble-free transfers. This method emphasizes careful handling of the film and specific application techniques to achieve high-quality results. Tutorials on UVDTF provide insights into optimizing your DTF process.

Can I wash fabrics with DTF transfers?

Yes, fabrics with DTF transfers can be washed, but it’s best to allow the design to set for at least 24 hours before washing. To preserve the integrity of the print, wash items inside out on a gentle cycle and avoid high heat drying.

| Key Point | Description |

|---|---|

| Introduction | DTF transfers are popular among crafters and small businesses for high-quality designs. |

| Understanding DTF Transfers | DTF uses a special film for transferring designs, offering versatility, durability, and ease of use. |

| Key Materials Needed | Materials include DTF transfer sheets, heat press or iron, Teflon sheet, scissors, and a flat surface. |

| Step 1: Preparing Your Design | Create or select a DTF-compatible design and adjust settings if using a cutting machine. |

| Step 2: Printing the Transfer | Print the design on DTF transfer sheets, ensuring high-quality ink and print settings. |

| Step 3: Prepping the Fabric | Wash and iron the fabric, then lay it flat on a hard surface before applying heat. |

| Step 4: Applying the DTF Transfer | Position the transfer on the fabric, cover with Teflon sheet, and apply heat for 15-20 seconds. |

| Step 5: Finishing Touches | Inspect the transfer, re-press if needed, and allow it to set for 24 hours before washing. |

| Innovations in DTF Transfers | New products like Insta DTF and UVDTF technology enhance application quality and ease. |

Summary

DTF transfers are a revolutionary method for applying vibrant designs to fabrics, combining ease of use and durability. This comprehensive step-by-step tutorial provides essential knowledge for both beginners and seasoned crafters looking to excel in DTF applications. By following the outlined steps and utilizing the right materials, you can achieve professional-quality transfers that stand the test of time. Keep informed about the latest innovations, as advancements like Insta DTF continue to enhance the DTF transfer experience, allowing for even greater creativity in your textile projects.