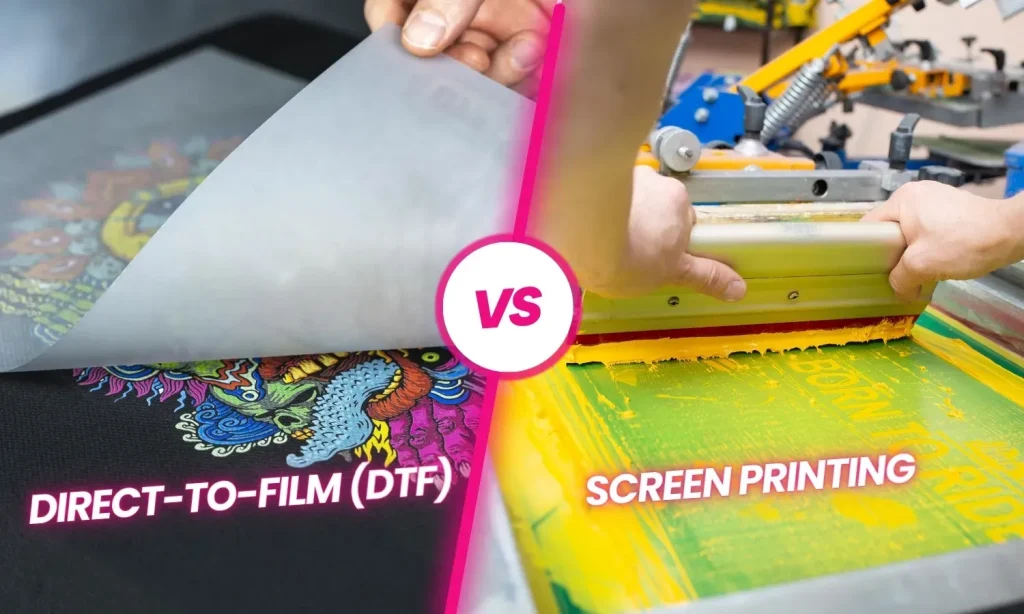

When it comes to customizing apparel, the debate of DTF Transfers vs. Traditional Screen Printing often arises, challenging businesses to choose the most suitable fabric printing technique. DTF printing has gained traction for its innovative approach, allowing for high-resolution designs that bring intricate artwork to life. On the other hand, traditional screen printing remains a time-honored favorite, known for its rich colors and solid coverage on fabric. Each method presents unique advantages and disadvantages, influencing factors like cost, durability, and scale of production. This comprehensive overview will explore DTF vs screen printing, shedding light on which printing process might be best suited for your custom apparel printing needs.

In the realm of garment decoration, the choice between Direct-to-Film (DTF) transfers and conventional screen printing presents a variety of options for businesses and designers alike. DTF techniques leverage advanced inkjet technology to produce vibrant graphics on film before transferring them to fabric, offering a modern twist to fabric printing methods. Conversely, the established practice of screen printing involves a more tactile process where inks are layered directly onto materials using screens. Both procedures have their distinct merits and challenges, leading to differing implications in terms of production costs, print longevity, and environmental impact. This article aims to break down the intricacies of these printing practices, guiding you towards the best decision for your apparel brand.

Understanding the Basics of DTF Printing

DTF (Direct-to-Film) printing is a cutting-edge technique that utilizes advanced inkjet technology to create stunning and detailed graphics on a film before transferring them onto fabrics. This method permits a vast spectrum of colors and gradient nuances, making it particularly advantageous for intricate artwork. The process enables businesses to cater to customer demands for unique and high-quality custom apparel while also streamlining production with minimal setup requirements.

By employing a heat press to apply the printed film directly to fabric, DTF printing provides not only vibrant designs but also the flexibility to handle short production runs. This approach is significantly advantageous for companies looking to implement on-demand printing solutions, as it reduces waste and enhances the overall sustainability of their operations. The growing popularity of DTF technology correlates with the rising demand for innovative fabric printing techniques that cater to modern consumer preferences.

The Evolution of Traditional Screen Printing

Traditional screen printing has been a staple in the garment decoration industry for decades, known for its ability to produce bold and vivid designs. This method involves the creation of stencils for each color, through which ink is squeezed onto the fabric. While the process can yield high-quality results, it requires significant setup time and costs, particularly for designs with multiple colors. Therefore, traditional screen printing often thrives in large volume productions, making it a popular choice for wholesalers and bulk orders.

Despite its age, screen printing continues to evolve, with many manufacturers adopting water-based inks to improve sustainability and reduce environmental impacts. The longevity and durability of screen-printed designs make them appealing, especially for brands that prioritize high-quality products. However, businesses must carefully consider the challenges associated with setup costs and print limitations when choosing between traditional screen printing and modern alternatives like DTF.”}]},{

DTF Transfers vs. Traditional Screen Printing: A Comprehensive Overview

When evaluating printing options, businesses often find themselves comparing DTF transfers against traditional screen printing. DTF printing stands out with its ability to produce complex designs that showcase a myriad of colors and details, surpassing the capabilities of screen printing for intricate artwork. Additionally, DTF transfers can be made on demand with lower initial investments and setup, making this method particularly appealing for smaller businesses or startups looking to enter the custom apparel market.

Conversely, traditional screen printing offers unparalleled durability and a quality that has made it a favorite among high-volume producers. The toughness of screen-printed designs—especially when using high-quality inks on the correct fabrics—ensures that the prints can withstand repeated washing without significant fading. Hence, while DTF transfers provide versatility and quick turnaround times, traditional screen printing remains a robust option for businesses focusing on bulk orders and longevity.

Production Flexibility in Custom Apparel Printing

The flexibility of production is a critical factor for businesses within the custom apparel printing industry. DTF printing excels in this category by allowing businesses to experiment with small batches and individual designs without the need for extensive setup processes. This adaptability means that brands can frequently update their offerings, catering to diverse customer preferences and on-trend designs.

On the other hand, traditional screen printing may hinder flexibility due to its reliance on creating individual screens for each design and color. While this process can yield dynamic prints in large quantities, the economic barriers it introduces make it less feasible for smaller runs or custom orders. As a result, businesses have to assess how their production needs align with the capabilities of each printing method to ensure they meet consumer demands effectively.

Cost Implications: DTF vs. Screen Printing

When considering the costs associated with DTF transfers and traditional screen printing, it’s essential to analyze the financial implications of each method for different production scales. DTF printing generally incurs lower initial setup costs, making it a valuable option for entrepreneurs entering the custom apparel space. As small businesses can manage smaller production runs without extraordinary financial commitments, DTF printing can provide a better return on investment for tailored orders.

In contrast, traditional screen printing offers diminishing costs per unit when scaled to larger orders. For those looking to produce high volumes of clothing, screen printing has a more favorable financial structure. However, businesses must be wary of the upfront investments required to create screens, particularly if they wish to diversify their product ranges with multiple colors and designs.

Environmental Impact of Printing Methods

As sustainability becomes a focal point for many businesses, understanding the environmental implications of different printing methods is paramount. DTF transfers, while traditionally involving more plastic components, have seen a shift towards water-based inks and eco-friendly substrates. Brands adopting DTF printing can market themselves with a smaller carbon footprint if they prioritize sustainable materials, even though practices can vary significantly across manufacturers.

Similarly, traditional screen printing is also transforming as more companies transition to using water-based inks in response to environmental concerns. While screen printing has historically posed challenges due to the usage of plastisol inks, recent developments are bringing eco-friendlier options to the forefront. Both printing methods are making strides toward sustainability, but businesses need to carefully choose their partners and materials to reduce their overall environmental impact.

Frequently Asked Questions

What are the main differences between DTF transfers and traditional screen printing?

DTF transfers utilize inkjet technology to print designs on a coated film, allowing for intricate and colorful prints. In contrast, traditional screen printing applies multiple layers of ink directly onto the fabric using stencils, making it excellent for bold designs but less flexible for complex colors.

How does the durability of DTF printing compare to traditional screen printing?

DTF printing offers good durability, but some prints may fade quicker than those from traditional screen printing, which is known for its long-lasting finishes. This can impact businesses focused on quality and longevity in their custom apparel.

Is DTF printing more cost-effective for small orders compared to traditional screen printing?

Yes, DTF transfers generally have lower initial setup costs and are more cost-effective for small runs, making it ideal for businesses that need to create custom designs without the expense of multiple screens required in traditional screen printing.

What are the environmental impacts of DTF transfers vs. traditional screen printing?

DTF transfers can vary in their ecological impact, but many processes are adopting eco-friendly materials. Traditional screen printing is also transitioning to water-based inks, reducing environmental harm. Thus, both methods are evolving towards more sustainable practices.

Which printing method is better for intricate designs: DTF printing or screen printing?

DTF printing is generally preferred for intricate designs due to its ability to produce detailed artwork without the need for multiple screens, making it a versatile choice compared to traditional screen printing.

Can DTF transfers handle larger production runs like traditional screen printing?

While DTF prints can manage larger orders, traditional screen printing excels in cost-effectiveness for substantial production runs due to lower costs per unit as quantity increases. Businesses should consider their production scale when choosing between these methods.

| Key Aspect | DTF Transfers | Traditional Screen Printing |

|---|---|---|

| Printing Technique | High-resolution prints with vibrant colors on a film substrate. | Manual printing with screens for each color, bold on lighter garments. |

| Production Flexibility | Ideal for small batches and unique designs; minimal setup time. | Cost-effective for large runs; not flexible for small orders due to high setup costs. |

| Durability of Prints | Good durability but may fade quicker with frequent washes. | Renowned for longevity and resilience against washing. |

| Cost Analysis | Lower initial costs, manageable for limited runs; may increase with volume. | Cost-effective for bulk orders but high setup costs for screens for smaller orders. |

| Environmental Considerations | Emerging eco-friendly options; sustainability varies by manufacturer. | Transitioning to water-based inks to reduce environmental impact. |

| Market Trends | Rising popularity in custom apparel; caters well to complex designs. | Still favored for bulk, traditional runs but adapting slowly to trends. |

Summary

DTF Transfers vs. Traditional Screen Printing encompasses a range of crucial comparisons for businesses considering their printing needs. In analyzing both methods, it is evident that DTF transfers offer innovative flexibility and an ability to handle complex designs, making them ideal for smaller runs and customizable orders. On the other hand, traditional screen printing excels in durability and cost-effectiveness during large production runs, appealing to businesses focused on wholesale orders. As sustainability takes center stage in the printing industry, both techniques are adapting to changes in consumer expectations and environmental impact. Ultimately, the choice between DTF transfers and traditional screen printing should align with a business’s specific needs, design capabilities, and market strategy.