When considering DTF vs DTG printing, businesses today find themselves navigating between two prominent methods that have reshaped the apparel industry. Direct-to-Film (DTF) printing utilizes a film transfer process, while Direct-to-Garment (DTG) printing directly applies ink to fabric. Both techniques come with unique benefits, making this a crucial printing methods comparison for brands aiming to meet diverse consumer demands. Understanding the nuances of DTF and DTG can significantly impact your production choices, ultimately influencing cost, quality, and market reach. As these printing technologies evolve, knowing which path to follow is essential for entrepreneurs looking to optimize their offerings.

In the world of modern printing, distinguishing between methods such as Direct-to-Film (DTF) and Direct-to-Garment (DTG) reveals vital considerations for businesses. These approaches differ not only in their processes but also in the types of products they best serve. DTF, which involves imprinting designs onto specialized film before applying them to fabrics, is ideal for versatility across various materials. In contrast, DTG excels in creating high-resolution prints directly onto textile surfaces, particularly cotton, making it the go-to choice for artists seeking detailed imagery. Understanding these alternative printing technologies is key as you navigate the evolving landscape of apparel production.

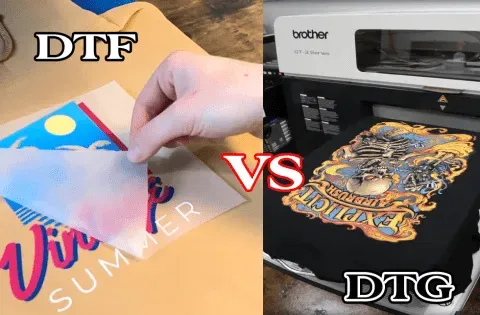

Comparative Overview of DTF and DTG Printing

When discussing apparel printing, the comparison between DTF (Direct-to-Film) and DTG (Direct-to-Garment) represents a pivotal decision for business owners. Each method offers unique advantages tailored to different market demands. DTF printing, known for its versatility, allows creators to effectively print designs on various fabric types, including blends and synthetics, making it a strong choice for diverse product lines. Conversely, DTG printing excels in delivering high-resolution images predominantly on cotton fabrics, perfect for establishments targeting customers who prioritize intricate designs and premium quality.

Moreover, the printing processes differ significantly between the two techniques. DTF utilizes a film transfer method which not only boosts the vibrancy and durability of prints on various materials but also enhances flexibility in production. In contrast, DTG operates by directly applying ink to fabrics, which typically results in softer prints that meld seamlessly with the fabric texture. This distinction makes each method suitable for specific product offerings, paving the way for businesses to align their printing strategy with their brand identity.

The Advantages of DTF Printing for Business

DTF printing holds remarkable advantages that can significantly benefit businesses aiming for a competitive edge. One prominent highlight of DTF is its ability to produce vibrantly colored prints on various materials, including polyester, cotton blends, and dark fabrics, broadening the scope of design possibilities. This method caters to businesses aiming for versatility in their clothing lines, enabling them to quickly adapt to shifting customer preferences. DTF also boasts faster production times, which is a boon for volume orders, making it ideal for enterprises that prioritize efficiency.

Additionally, the cost-effectiveness of DTF becomes increasingly apparent in larger production runs. While initial equipment investments may be substantial, the printing costs per unit decrease significantly with higher volumes, ensuring profitability for businesses focused on scaling up. The capability to handle multiple orders without compromising on quality also positions DTF as a favorable choice for companies venturing into customized apparel, meeting both quantity and design demands.

Exploring the Benefits of DTG Printing

On the other end of the spectrum, Direct-to-Garment (DTG) printing offers its own set of compelling benefits. Primarily recognized for its high-quality output, DTG is preferred for detailed artwork, allowing artists and businesses to bring complex designs to life with stunning clarity. Since DTG directly inks garments, it enables soft, high-resolution prints that retain the fabric’s natural feel, elevating customer satisfaction for those looking for premium apparel.

Furthermore, DTG is an excellent solution for small batch runs and one-off creations, making it ideal for niche markets and artisanal businesses. This capability allows for customization and personalization, catering to a clientele that values unique, tailored garments. While the initial investment may be higher, DTG’s efficacy in producing short runs makes it a feasible option for businesses that seek to offer bespoke designs without the need for large inventories.

Understanding Print Quality Differences in DTF and DTG

When evaluating printing methods, print quality emerges as a critical factor in the DTF vs DTG debate. DTF printing is acclaimed for producing vibrant prints that hold up well on a variety of fabric types, particularly on darker materials where colors can pop and achieve a glossy finish. This quality makes DTF particularly appealing for businesses focused on producing eye-catching apparel that stands out in a crowded marketplace.

Conversely, DTG printing’s hallmark is its ability to achieve superior detail and color accuracy, especially on cotton garments. The intricacy and softness of DTG prints allow them to integrate seamlessly into the cloth, providing a luxurious feel that appeals to high-end consumers. Businesses that wish to highlight artistic designs and detailed illustrations will find that DTG delivers a level of quality that often surpasses that of traditional screen printing, distinctly positioning them in the premium segment.

Economic Aspects of DTF and DTG Printing

The financial considerations surrounding DTF and DTG printing methods are influenced by various factors, including initial investments, production efficiency, and material costs. DTF printing may demand an upfront investment for equipment and transfer materials, yet its efficiency and lower cost per unit in large orders can significantly offset these expenses. Consequently, businesses focused on bulk production or a wide range of offerings might find DTF to be a more economically viable choice in the long run.

In contrast, DTG printing typically involves a higher initial outlay for printers and inks; however, it shines in situations where businesses require high-quality outputs for smaller order quantities. The ability to execute rapid production of personalized items translates into quick returns on investment, making it attractive for startups and small businesses that cater to specific market niches without the need for extensive inventory.

Future Trends in Apparel Printing: DTF and DTG

As the apparel printing landscape continues to evolve, the trends for both DTF and DTG methods shift in response to consumer demand and technological advancements. DTF printing is gaining traction for its eco-friendly capabilities, such as reduced waste and recyclable materials, aligning with the current consumer trends favoring sustainable production processes. This growing trend toward customization and diverse fabric compatibility positions DTF as a frontrunner in the future apparel markets.

Meanwhile, DTG remains strong due to its long-standing reputation for outstanding print quality and the evolving capabilities of inkjet technology. As more businesses embrace e-commerce and on-demand production models, the ability of DTG to deliver high-quality prints for small orders ensures its relevance in the market. The combination of these technologies staying attuned to consumer preferences is likely to redefine the industry, encouraging businesses to reassess their printing strategies based on emerging trends.

Frequently Asked Questions

What are the major differences between DTF and DTG printing methods?

DTF (Direct-to-Film) printing transfers designs onto fabrics using a special film and heat, offering versatility across different materials. In contrast, DTG (Direct-to-Garment) printing directly applies ink onto fabric, primarily excelling with cotton. Both methods vary in print quality, cost, and efficiency.

Is DTF printing more versatile than DTG printing?

Yes, DTF printing is generally considered more versatile because it works effectively on various fabric types including cotton, polyester, and blends. DTG printing is more limited, primarily performing best with cotton fabrics.

Which printing method delivers better print quality, DTF or DTG?

DTG printing is known for superior print quality, especially for intricate designs, as it integrates ink directly with the fabric for a soft finish. However, DTF also provides good color vibrancy, particularly on darker fabrics, making it suitable for certain applications.

What are the cost implications for businesses choosing between DTF and DTG?

Initially, DTG printers tend to require a higher investment, but they can be cost-effective for short runs. DTF may require substantial upfront costs for films and equipment, but it can be more economical for high-volume production as costs per print decrease.

Can businesses utilize both DTF and DTG printing methods?

Absolutely! Many businesses leverage both DTF and DTG printing methods to cater to different customer needs. DTF is excellent for bulk orders and diverse fabrics, while DTG is ideal for high-quality, personalized designs.

What trends are emerging in DTF vs DTG printing?

The trend is leaning towards DTF due to its adaptability and growing demand for customization. However, DTG remains stable as a trusted method for high-quality prints, particularly for small orders and artists looking for detailed artistry.

| Criteria | DTF (Direct-to-Film) | DTG (Direct-to-Garment) |

|---|---|---|

| Process and Technology | Transfers designs from film to fabric, versatile on multiple materials | Applies ink directly to fabric, best on cotton, high-quality prints |

| Print Quality | Good color vibrancy, excellent on darker fabrics, matte or glossy finishes | Superior print output with intricate designs, softer feel on fabric |

| Cost and Efficiency | Higher initial investment but reduces costs in bulk production, fast for large orders | Higher initial investment for printer, cost-effective for short runs, quick for custom jobs |

| Market Trends | Growing demand for customization and eco-friendliness, adaptable for many types | Stable growth for high-quality prints, favored for small orders |

Summary

DTF vs DTG where the emphasis is on understanding which printing method best suits your business needs is crucial. DTF is particularly advantageous for flexibility, working across various fabric types, and excelling in bulk orders, making it ideal for businesses that cater to a diverse customer base. In contrast, DTG offers superior print quality and is preferred for high-resolution designs on cotton, appealing to artists and those who wish to create unique, custom pieces. Ultimately, choosing between these methods requires careful consideration of market demands, order sizes, and production capacities to ensure alignment with your business objectives.